NFPA 70E Arc Flash with OSHA Signs

03

February,

2023

3 MINUTE READ

What is NFPA 70E?

NFPA 70E, or the NFPA's Standard for Electrical Safety in the Workplace, outlines specific practices to be followed in protecting workers from electrical hazards such as arc flash. Learn how to enhance electrical hazard protection with OSHA signs according to NFPA guidelines, using the DuraLabel Kodiak Max Industrial Sign and Label Print System. Create compliant signs easily with premade NFPA, ARC Flash, and Electrical Safety LabelForge labels and signs.

The National Fire Protection Association (NFPA) is a non-profit organization that produces standards for safety. In many parts of the United States, this code has been incorporated into law and aligns with Occupational Safety and Health Administration (OSHA) standards.

For safe electrical work in an existing facility, the "go-to" standard is NFPA 70E. While it is not legally required in most areas, it is widely respected and used as a reference for safe practices worldwide.

The NFPA 70E Electrical Safety Program

To ensure that safety procedures are implemented and consistently applied, NFPA 70E requires companies to create a written electrical safety program. This program should include:

- the training requirements for the types of work that will be done in the facility

- assessments of any electrical hazards in the facility, such as arc flash

- the specific procedures for necessary maintenance of the facility's equipment

- Up-to-date and accurate information on the facility's electrical systems

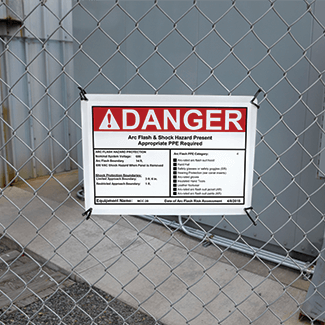

The goal of the program is to protect the workers and facility from harm. An effective system should establish a culture of safety awareness that includes all employees. One key part of safety awareness is providing information about any hazards that exist, so NFPA 70E includes detailed requirements for hazard and equipment labeling. Thankfully, these standards will also comply with OSHA label requirements. The current edition of the standard requires detailed labels, not just generic warnings. These practices align with OSHA labeling requirements, ensuring comprehensive safety protocols.

Electrically Safe Work Conditions

Wherever possible, NFPA 70E requires the establishment of an "electrically safe work condition" before electrical work begins. This means that the equipment is fully de-energized and cannot be re-energized while work is still being performed. The following steps should be taken to create an electrically safe work condition:

- Determine all possible sources of electrical energy to the equipment.

- Shut down the equipment and disconnect each source of energy.

- Visually confirm that disconnections are complete with the proper OSHA signs and labels.

- Apply appropriate lockout / tagout devices that meet OSHA electrical panel labeling requirements to prevent re-connection of those power sources.

- Verify that each part of the equipment is de-energized using appropriate test instruments, such as voltmeters. Until the equipment is tested, assume that it is still energized.

- Use grounding devices in areas where induction or accidental contact with energized parts may occur.

Once this process has been completed, the equipment will no longer carry any significant current or charge. Creating an electrically safe work condition is the best defense against electrical hazards such as shock and arc flash (a sudden and dangerous burst of energy). As a result, this procedure should be used in all electrical work, with the following exceptions:

- De-energizing equipment would create a greater hazard. Examples include life-support equipment, ventilation equipment in a hazardous environment, or similar safety equipment that requires an energized state.

- De-energizing is not possible, due to equipment design. If the equipment is part of a larger, continuously operating system, for example, it may not be possible to de-energize the necessary parts.

- The performed work requires that equipment be energized. An example is checking voltage.

Proper NFPA 70E training in these procedures confirms that workers understand the importance of electrically safe work conditions and follow correct procedures to mitigate electrical hazards.

What is NFPA 70E's Standard for Dealing with Arc Flash?

While electrically safe conditions are effective for protecting workers, the act of creating an electrically safe condition requires a worker to interact with equipment that is still powered.

While electrically safe conditions are effective for protecting workers, the act of creating an electrically safe condition requires a worker to interact with equipment that is still powered.

Where live work must be performed, including the work of implementing an electrically safe condition, one of the major concerns is the risk of an arc flash. This hazard is especially dangerous because arc flashes occur most often during equipment maintenance when a worker is interacting directly with the equipment. Small arcs can arise whenever equipment is installed or removed, and whenever disconnecting switches are opened or closed. If the arc blast is sustained, it can become incredibly destructive in the blink of an eye, becoming an arc flash. NFPA 70E focuses a significant part of its content on this one hazard.

The standard uses a sequence of protective elements to limit the likelihood of an arc flash occurring and to limit the harm that results if there is an arc flash.

NFPA 70E requires protective boundaries around potentially hazardous equipment as a beginning step for safety. These boundaries keep unprotected individuals at a safe distance. The arc flash boundary infographic shows the three major boundaries from NFPA 70E and explains how they can help keep your workers safe.

The last line of defense against an arc flash is personal protective equipment (PPE) signage, and NFPA 70E provides recommendations and requirements, along with proper OSHA label requirements, for that equipment. PPE comes in a variety of types and levels of protection, so the NFPA has allowed several ways for facilities to describe the kinds of PPE that will be needed for work. The simplest system is a series of categories, clearly shown in this arc flash reference chart.

Whether you need safety signs, pipe markers, or equipment labels—Toro Max and Kodiak Max are ready to transport anywhere you are. Get help crafting a system that will provide the safety communication you need. Call 1-888-326-9244 and one of our experts will guide you through the process. Learn more about arc flash labels to ensure workers are aware of the equipment's hazards before they are exposed to those hazards. Download our free guide to Arc Flash Instant Action Guide

Read Next:

4 Hazards of the Electric Power Industry and How to Eliminate them

RELATED RESOURCES

OSHA and NFPA 70E

When workers performing maintenance or repairs on energized electrical equipment, they could be exposed to an ...

Read

Arc Flash in Mining

Very little can happen in mining without electricity. From drilling equipment and powered shovels to fixed ...

Read

Strengthening Arc Flash Hazard Analysis with OSHA Signs

Conducting an arc flash hazard study is the cornerstone for worker safety when working with live equipment ...

Read.png)