Safety and Supply Chain Management Go Hand in Hand

03

February,

2023

2 MINUTE READ

The supply chain is the flow of raw materials to manufacturer, to distributor, to customer, to consumer. Supply chain managers are responsible for identification, acquisition, production and distribution of the goods a company provides its customers.

Key supply chain management skills include a thorough knowledge of manufacturing processes, transportation and logistics, warehousing and information. Supply chain managers are excellent communicators who use both verbal and visual communication tools including keeping track of inventory with labels on packaging and in storage locations.

Supply chain management encompasses nearly every product we touch in every grocery store, hardware store or pharmacy around the world.

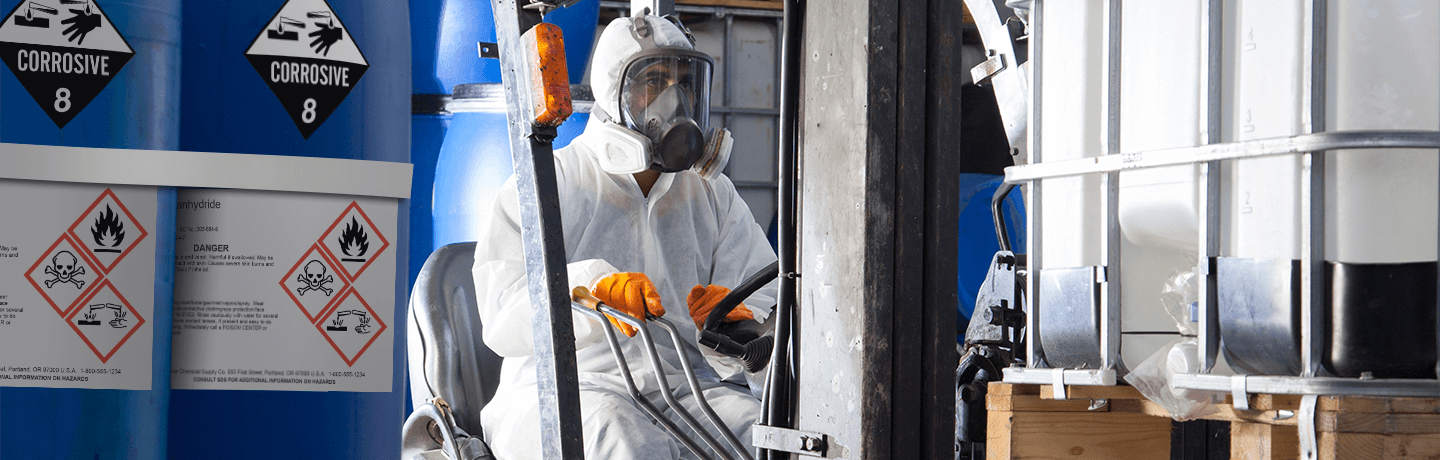

One of the key themes throughout the supply chain is safety. Consider the manufacturing phase of the supply chain.

Garment workers in Bangladesh and China are often unprotected from dangerous working conditions including fire, electrical and building safety.

Major brands such as Adidas, Abercrombie & Fitch and Fruit of the Loom have signed a fire and building safety accord which has helped increase the number of safety inspectors in these countries. Brands who've signed on must also provide financial assistance to factory owners to make them safer.

But there's still a lot more work to be done to support safety at every phase or stage of the supply chain.

Here in Portland, our friend manages a teaching farm for the Oregon State University Extension program. Jen's supply chain is relatively short ? from a community farm to her home to my home ? a distance of about ten miles. Twenty families have signed on as subscribers. The model is sustainable and is as important as cost, value and speed.

But there are safety and operational considerations even within a short supply chain. Jen's got to drive the speed limit, obey traffic signs and signals, and make sure her crew is adequately hydrated throughout the day.

During the growing season, critical safety considerations come into play, including:

- Providing proper sanitation and hand washing facilities in areas outside the field.

- Providing areas outside fields for eating, breaks, smoking and storage of personal items.

- Cleaning and sanitizing tractors and other implements that were used in manure application and incorporation prior to entering the field.

- Ensure that water used for spray applications of pesticides and fertilizers is not contaminated.

- Sick employees should not have direct contact with produce. Assign them other duties while they are sick or send them home. Employees who cut themselves should wear gloves and use bandages until the wound is healed.

The small farmer is a microcosm of the global supply chain manager. While the farm is operating from spring to fall, she's got planning and forecasting to do in the winter. How many crops (raw materials) should she plant? How many families will sign up (customers)? How much should she charge per family (pricing)? Which students will most likely grasp Jen's approach to farming and be willing to do the backbreaking work to make the farm succeed (talent management)? How do all these stages vary from harvest to harvest? As a supply chain manager, she's ultimately got to ensure that her produce is safe from contamination.

Both local and global supply chain managers face several challenges:

- Strategic planning across the supplier, manufacturing, customer and product footprints.

- Higher velocity and responsiveness to market.

- Better talent management of supply chain professionals who have a strong foundation with end to end supply chain thinking.

Whether you're managing a community or a worldwide supply chain, the issues and challenges are consistent. Remember, you're not alone in obsessing over every detail 24/7/365.

RELATED RESOURCES

Materials Handling Equipment

Last month, a New York City window cleaner fell over 30 feet to his death in midtown Manhattan. He fell after ...

Read

1910 138 Hand Protection

Examples of injuries to your employees' arms and hands are burns, cuts, electrical shocks, amputation, and ...

Read

Hazardous Materials Identification System (HMIS) and OSHA Signs

Decoding HMIS and OSHA Signs: Creating Safety in Hazardous Environments In hazardous environments, ...

Read.png)