Arc Flash Accident Reports

03

February,

2023

9 MINUTE READ

An arc flash is dangerous and has the potential for causing serious injuries. It typically occurs suddenly and without warning - but not without a cause. Many arc flashes are caused by human error. The arc flash could have been avoided and the seriousness of arc flash injuries could have been reduced by those involved having followed proper procedures.

We'll take a look at the accident reports for five arc flash incidents to see if we can determine what happened; what should have been done differently; and how the accident could have been prevented.

The five arc flash accidents are:

- Arc Flash #1: On April 14, 2006, at the Brookhaven National Laboratory (BNL), an electrical engineer was injured by an arc flash while closing a fused-disconnect switch in an electrical panel.

- Arc Flash #2: On an oil drilling platform in the Gulf of Mexico, on November 20, 2009, an electrician was investigating the cause for the loss of electrical power. While the electrician was inside the Motor Control Center (MCC) building, an arc flash occurred in a 480 volt breaker panel that resulted in first degree burns on the electrician's face and neck.

- Arc Flash #3: In Queensland, Australia on Thursday June 15, 2006 a Field Service Technician- Electrical, received severe burns when an 11000 volt arc flash explosion occurred inside a main incomer circuit breaker cubical.

- Arc Flash #4: On October 11, 2004 an electrician working at the Stanford Linear Accelerator Center (SLAC) received serious burn injuries requiring hospitalization due to an electrical arc flash that occurred during the installation of a circuit breaker in an energized 480-Volt (V) electrical panel.

- Arc Flash #5: On September 23, 2009, at the U.S. Department of Energy Savannah River Site, two electrical and instrumentation mechanics were troubleshooting a problem in a 480-volt circuit breaker cubicle when an arc flash occurred. One mechanic suffered second- and third-degree burns to his arms and face. The second mechanic was not injured because he had stepped away from the cabinet before the arc flash occurred.

#1

An electrical engineer was injured by an arc flash while closing a fused-disconnect switch in an electrical panel. The electrical engineer, who was not wearing appropriate clothing nor the required PPE, received first and second-degree burns to his face and body.

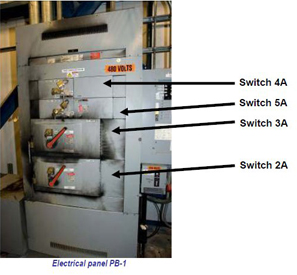

The electrical engineer had been called in to help two electronic technicians troubleshoot a high-current ripple problem. Once the problem had been solved, they began restoring electrical power. The electrical engineer was closing four fused-disconnect switches on the 480-volt panel. When the third switch was closed he heard a very loud noise and saw sparks and smoke coming from within the panel.

The arc flash created radiant heat energy and molten aluminum, most of which was contained within the panel and was vented away from the electrical engineer. However, what was expelled from the front of the panel set his hair on fire and caused first-degree burns on his face, scalp, and chest. He also received first and second degree burns on his hands and forearms and a corneal abrasion to his left eye.

Accident Report Results

The cause of the arc flash is believed to be an over-voltage condition resulting from a ground fault on an underground cable. This resulted in the initial arc between the grounded steel frame and the phase B bus. This arc resulted in phase-to-phase arcing within the switch.

The following are some of the conclusions in the accident report:

- BNL failed to ensure that ground-fault monitoring detection was operable. The ground-fault relays were not included in a preventive maintenance program.

- BNL failed to comply with the requirements of NFPA 70 / NEC 2005 for ground fault protection, which requires detectors for some specific applications of ungrounded electrical systems.

- There was a failure to implement formal work controls for working on ungrounded delta systems that could have a ground fault.

- The NFPA 70E requirements were not implemented. Arc flash calculations for the building where the incident occurred were not completed and warning labels had not been posted.

- The Department Conduct of Operations Program was not followed. Pre-job briefings were not held; personnel did not stop work when they observed the electrical engineer not wearing proper PPE; and surveillance of ground-fault conditions were not formalized through approved procedures.

- There was a failure to wear appropriate PPE when approaching and operating the switches on the electrical panel. The electrical engineer was not wearing flame resistant clothing, nor eye protection, nor any other PPE.

The accident report recommendations included:

- Conduct engineering evaluations of ungrounded delta electrical systems throughout the site.

- Immediately verify that all ground-fault monitoring devices are connected to remote alarms in the Main Control Room.

- Determine and review the specific factors by which design reviews and approval processes failed to ensure installation of a functional ground-fault monitoring and alarm system as specified in standards and required by the DOE. Additionally, implement the corrective actions identified by this review to prevent recurrence.

- Develop, train, and implement formal work controls to address receipt of initial ground-fault alarms.

- Establish a preventive maintenance inspection program for electrical distribution system equipment to include fused-disconnect switches and ground-fault relays.

- Establish a preventive maintenance inspection program for fused-disconnect switches and ground-fault relays.

- Establish a formalized project management process for arc flash calculations that establishes priorities, resources, and accountability.

- Conduct an independent effectiveness review of the implementation of the personal protective equipment and training requirements of NFPA 70E.

- A commitment to label all panels with arc flash hazard labels.

- Strengthen the Conduct of Operations Program to ensure procedural adherence, formality of operations, performance of required job briefings, and the exercise of stop-work authority.

#2

An electrician was investigating the cause for the loss of electrical power to the Quarters building. While in the MCC building an arc flash occurred in a 480 volt breaker panel. The electrician received first degree burns on the left side of his face and neck. The fire alarm bell automatically activated when the MCC building sensors detected smoke, and a total platform shut-in was initiated with all personnel mustered to their designated duty stations.

Accident Report Results

The arc flash incident investigation determined that a cable gland, mated to a Hub connector, was loose. This allowed rain and salt water spray to enter into the junction box. The water migrated by gravity feed approximately 185 feet through a conduit void from the power breakers to the Topside Control Center breaker enclosure.

The breaker internals showed evidence of water entrance and corrosion which suggests that small amounts of water entered the Quarters building power breaker over a long period of time. The water build-up inside the breaker broke down the insulation between phase A and phase B, and the arc flash was caused by a short between phase A and phase B.

There were no recommendations in the accident report.

#3

A Field Service Technician- Electrical, working in a switch room, received severe burns when an 11,000 volt arc flash explosion occurred inside a main circuit breaker cubical.

Accident Report Results

The investigation was not able to determine the cause of the arc flash. There was no evidence of:

- Mechanical failure

- Electrical supply abnormalities

- Vermin

- Moisture

- Foreign objects

- Excessive dust

It was noted that the safety shutters were not correctly labeled and there was the possibility of the failure of one shutter. In addition, the high voltage receptacles were not labeled.

Several factors contributed to the severity of the injury. Although the electrician had received the required training and a risk assessment had been carried out, the electrician was not wearing the correct PPE and had not followed required procedures.

The accident report recommendations included:

- The accident report recommendations included:

- Audits of all high voltage circuit breakers be conducted to:

- Confirm that the isolation of safety shutters can be done safely.

- Verify the correct labeling of high voltage receptacles.

- Ensure switching, access and working permits are issued prior to working on high voltage equipment.

- Ensure high voltage is isolated external to the work area.

- Ensure procedures and standards include the use of proper arc fault protective clothing and equipment.

#4

On the morning of October 11 an electrician was directed to install a new circuit breaker in an energized electrical circuit breaker panel. The supervisor had chosen the panel because it had an available slot for an additional circuit breaker.

At approximately 11:15 am, while the electrician was installing the new circuit breaker, an arc flash occurred igniting the electrician's clothing. The electrician received third degree burns on the face, chest, and legs and second degree burns on his arms. Approximately 50% of his body was burned. Because of the seriousness of his injuries, investigators were not able to interview the electrician.

Accident Report Results

The results of an accident analysis concluded that arc flash was caused by the following:

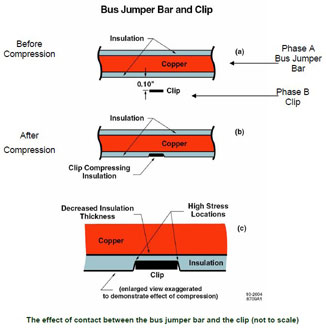

The proper installation sequence for a breaker would have been to install the mechanical connections first. This would mechanically stabilize the breaker before making the electrical connections. The investigation revealed that none of the mechanical connections had been made, and phases B and C had been connected. The electrician was attempting to connect phase A but was having trouble with getting the screw to hold.

The investigation concluded that the electrician was using extra force to push on the screw in an attempt to get it to engage the threads on the bus link. This resulted in the phase A bus jumper bar deflecting toward the phase B stabilizing clip. The rubber insulation was compressed which increased the electric field stress in the insulation. The increase in electric field stress caused a failure of the insulation and resulted in an arc flash.

The following are some of the conclusions in the accident report:

- There was no justification for installing the breaker in energized Panel 4P20R.

- The OSHA required (29 CFR 1910.132 - PPE) hazard assessment requirements for breaker installation were not conducted.

- The employer's practices regarding working on or near energized electrical equipment violated OSHA standards which say:

Live parts to which an employee may be exposed shall be deenergized before the employee works on or near them, unless the employer can demonstrate that deenergizing introduces additional or increased hazards or is infeasible due to equipment design or operational limitations. - 29 CFR 1910.333(a)(1).

- The employer did not ensure that electrical protective equipment appropriate for the specific parts of the body to be protected from arc flash hazards was used as required by OSHA:

Employees working in areas where there are potential electrical hazards shall be provided with, and shall use, electrical protective equipment that is appropriate for the specific parts of the body to be protected and for the work to be performed. - 29 CFR 1910.335(a)(1)(i).

- The employer failed to identify safety-related work practices (such as those included NFPA 70E) to protect the employees who were exposed to the electrical hazards involved with working on live electrical equipment.

- The screwdriver the electrician was using was not insulated and violated OSHA 29 CFR 1910.335(a)(2)(i).

- Unsafe conditions and operations have become an accepted part of the everyday way of doing business.

The accident report recommendations included:

- Management needs to enforce applicable OSHA standards and all sections of NFPA 70E.

- Management needs to ensure that employees who work on or near exposed energized electrical conductors are trained on the implementation of electrical safety-related work practices.

- Management, and subcontractor supervisors and managers, need to receive the same training as the workers.

- Ensure that legal interpretations used to establish each employer's worker protection responsibilities are consistent with OSHA's interpretations on multi-employer workplaces.

- Management needs to develop and implement safety oversight programs designed to identify deficient electrical work practices and correct them in a timely manner that achieves continuous improvement.

- Need to ensure that employees at all levels fully understand that concern for mission accomplishment does not outweigh the need for safe operations.

#5

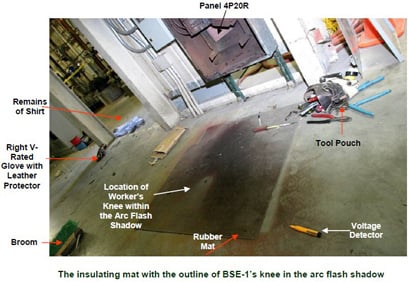

Two E&I Mechanics were troubleshooting a breaker that would not close. The breaker was located in an energized cabinet. A 9-inch torpedo type level was being used to level the track that was causing breaker misalignment. The level fell from the top of the chute down the left side of the breaker and is suspected of having lodged between the phase "A" breaker moving contact and the breaker support brace, resulting in an arc flash.

The arc flash severely damaged the left side of the breaker, splattered material in the cabinet and surrounding area, and embedded slag in electrical equipment ten feet away.

One of the E&I Mechanics, who was not wearing a flash suit nor flame-retardant coveralls, noticed the level fall and covered his head and face with his arms. He received second and third degree burns on his arms, and first and second degree burns on the right side of his face. The other E&I Mechanic had stepped away from the cabinet and was outside the effect of the arc flash.

Accident Report Results

Based on the condition of the circuit breaker and cubicle, the investigation determined the fault current was interrupted before the short was able to develop a plasma arc cloud which would have made the event a fully engulfed arc flash and creating more extreme consequences and injuries.

- A perfunctory pre-job briefing was conducted, and failed to communicate the mechanic's specific tasks, the arc flash and shock hazards, or to identify the required personal protective equipment.

- Experienced Qualified Electrical Workers failed to comply with general safe work practices and electrical procedures.

- The work scope was poorly defines and outside of the scope of established safe work practices.

- The Experience Qualified Electrical Workers disregarded proper implementation of hazard controls and failed to comply with the required work planning and control practices by beginning corrective maintenance with no specific authorization or work package, and continuing corrective maintenance with a work package that did not cover the scope of the activities being conducted.

- Management failed to ensure work was performed safely.

The accident report recommendations included:

- Management needs to ensure that work is reviewed, authorized, supervised and performed by personnel who clearly understand the work scope, limitations, hazards, and controls prior to work execution.

- Management needs to ensure troubleshooting work is controlled by a job-specific work order in compliance with established procedures.

- Management needs to develop a process to ensure adequate control of tools and equipment used on or near energized electrical components.

- Management needs to ensure that effective pre-job briefings are conducted in accordance with established procedures.

- Management needs to reduce an existing excessive reliance on Qualified Electrical Workers' knowledge as the single line of defense in identifying needed controls for electrical work.

Comprehensive Arc Flash Safety Plan

Arc Flash is a complex topic which requires education to reduce accidents and improve workplace safety. We've helped to create a free 130-page Guide to Arc Flash Hazards which has absolutely everything you'll need to keep your facility safe. Download your free copy below.

RELATED RESOURCES

Arc Flash PPE

Personal Protective Equipment (PPE) is the last line of defense against injuries. When it comes to arc flash, ...

Read

OSHA and NFPA 70E

When workers performing maintenance or repairs on energized electrical equipment, they could be exposed to an ...

Read

Strengthening Arc Flash Hazard Analysis with OSHA Signs

Conducting an arc flash hazard study is the cornerstone for worker safety when working with live equipment ...

Read.png)