Wire Color Coding

03

February,

2023

3 MINUTE READ

There are many wire identification standards, and many of them rely on color codes. Not all electrical wiring color codes are the same, though, and some even contradict each other. Which standard should be used in your facility? It depends on your location, installation type, voltage, and other factors.

Note that older installations may use different color codes. In workplaces, it's a good idea to document the color code that is being followed. This way, work will be safer, and future maintenance will be easier.

U.S. Electrical Wiring Color Codes

In the United States, the following color codes are typically used for power wires in "branch circuits," the wiring between the last protective device (such as a circuit breaker) and the load (such as a tool or appliance).

120/208/240 Volt AC Wire Colors

These systems are common in home and office environments.

- Phase 1 - Black

- Phase 2 - Red

- Phase 3 - Blue

- Neutral - White

- Ground - Green, Green with Yellow Stripe, or Bare Wire

If the wiring system has one phase at a higher voltage than the others, using a "high-leg" connection, that phase's wires should be marked with orange. (This is required in NEC article 110.15.) However, these high-leg delta systems are uncommon with newer installations.

277/480 Volt AC Wire Colors

These higher-voltage systems are common for industrial motors and equipment.

- Phase 1 - Brown

- Phase 2 - Orange

- Phase 3 - Yellow

- Neutral - Gray

- Ground - Green, Green with Yellow Stripe, or Bare Wire

For higher-voltage cases, it becomes even more important to have a documented wire labeling system. More detailed labels can include information like circuit identification, or the appropriate disconnection point for lockout/tagout.

DC Power Wire Colors

Solar power systems and many battery systems use DC (direct current) power, rather than AC (alternating current).

- Positive (non-ground) - Red

- Negative (non-ground) - Black

- Ground - White or Gray

International Electrical Wiring Color Codes

The color codes used for wires can vary. In some areas, a color code is specified by law; other areas rely on common practice. Different codes are popular in different areas.

European (IEC) Wire Color Codes

Most European countries follow a wire color code established by the International Electrotechnical Commission (IEC) for AC branch circuits. This standard was originally published as IEC 60446, but was merged into IEC 60445 in 2010.

- Phase 1 - Brown

- Phase 2 - Black

- Phase 3 - Grey

- Neutral - Blue

- Ground - Green with Yellow Stripe

Canadian Wire Color Codes for AC Power

In Canada, wire color coding standards are set by the Canadian Electric Code (CEC). The color code for AC power wiring is similar to the code used in the United States:

- Phase 1 - Red

- Phase 2 - Black

- Phase 3 - Blue

- Neutral - White

- Ground - Green with Yellow Stripe

Data Wire Color Coding

Wiring used for telecommunications or computer network applications use a different approach for identifying data cables. The ANSI/TIA/EIA 606-A standard includes recommendations for marking telecommunications wires. This standard provides a consistent approach that can be applied to many different kinds of connections over time.

While color can rapidly provide some information, the amount of information is limited. For example, if a cable marker is blue, that might indicate that it's part of a specific subgroup of the local network. Printed text on the label, though, could identify which specific workstation uses that cable, which port on the server it should be connected to, as well as when the cable was installed. With information wiring, printed labels can be a necessity.

Wire markers should be visible during installation and normal maintenance of the wiring systems. When those labels use printed text, they should use high-contrast and durable print. Whatever marking system is used for the cables and wires in your facility, the markings should be durable enough to last as long as the wires themselves.

Applying Color Codes to Electrical Wiring

Most narrow wires will be color-coded by the manufacturer, using insulation of different colors. When wires are larger than #6 AWG, they will typically be manufactured with black insulation. In these cases, color coding should be added during installation, using colored bands that wrap around the wire.

Where more detailed information is helpful (or even necessary), the DuraLabel line of label printers offer a simple and reliable way to print long-lasting markers and wire tags. Self-laminating wire wraps and heat-shrink tubes are available to create clean, professional labels for your project.

RELATED RESOURCES

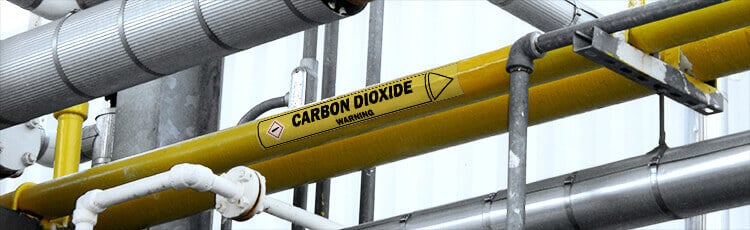

Pipe Marking Basics

Pipes can put people and facilities in danger if no one knows what's flowing through them. Pipe labels help ...

Read

DOT Labels

49 CFR 172.400 specifies that Department of Transportation (DOT) Labels must be used for hazardous materials ...

Read

UK Pipe Marking: Regulations vs. Standards

UK Pipe Marking When it comes to pipe marking in the United Kingdom (UK), there are two commonly cited ...

Read.png)