Tips from a Brewer for Effective Floor Marking

24

January,

2024

6 MINUTE READ

Hold My Beer: 5 Floor Marking Tips from a Brewery

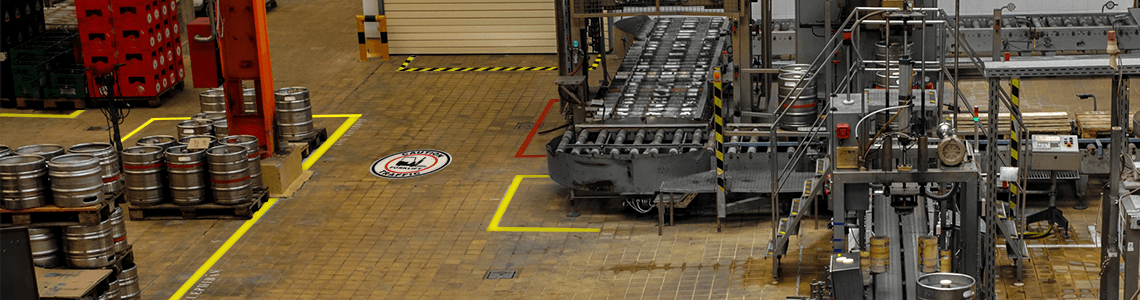

In the heart of the brewery, every step is important for the perfect pint. To keep things running smoothly, breweries know the importance of maintaining a safe and organized workspace. From navigating around towering tanks to ensuring the smooth flow of operations, floor marking plays a vital role in keeping a brewery running like a well lubricated machine. Smart facility managers understand the uses and benefits of floor marking, health and safety rules and regulations, and challenges faced in developing a floor marking system. Grab your tasting glass and tap into the wisdom of breweries to serve up five refreshing floor-marking tips.

Here are 5 Floor Marking Tips from a Brewery:

1) Recognize the Benefits

Any facility can benefit from a cohesive floor marking and wayfinding system, whether you are making beer, mixing chemicals, or producing goods. Knowing these benefits can help communicate the value of the project to team members and enhance the effectiveness of a floor marking plan. Here are three benefits:

Increase safety: With clear paths and visual communication from floor tapes, employees are more aware of hazards that might be present and may take precautions to work safely.

Improve efficiency: Wayfinding can establish clear navigational routes, which in turn help employees quickly find their way around a facility.

Enhance organization: Warehouse floor marking tape can clearly outline where certain pieces of equipment (such as pallets) should be stored, making it easier for employees to find (or put away) items when necessary.

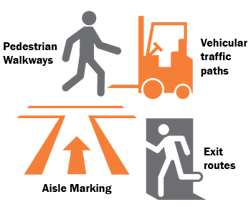

Here are a few ways a system improves workflow and safety in a facility:

- Organize all workspaces: Floor tapes and signs makes it easier to find equipment and safely move around facilities. It can also designate areas specifically for inventory and equipment (when not in use).

- Create pedestrian walkways: With effective industrial floor marking tape and signs, pedestrians know where to go and, most importantly, where not to go in crowded workspaces.

- Outline forklift and powered truck paths: Well-marked paths with safety floor tape can help pedestrians and powered truck drivers work safely together. The recommended aisle width is at least 3 to 4 feet wider than the largest piece of equipment utilized in the area.

- Mark aisles and exit routes: Using marking tape to mark paths and exit routes can maintain order and usher workers to safety in case of emergency, and glow-in-the-dark warehouse floor tape can assist during power outages.

2) Know Floor Marking Rules and Regulations

OSHA establishes fundamental rules and regulations concerning floor marking, with the agency's standard outlined in 29 CFR 1910.22. However, most decisions about floor signage are left to individual employers. While 29 CFR 1910.22(b)(2) specifies that permanent aisles and passageways should be appropriately marked, the broader standard does not provide guidelines for colors unless it is utilized for preventing physical injuries.

Nonetheless, 29 CFR 1910.144, OSHA's standard for delineating safety color codes, specifies that red and yellow are designated safety color codes for marking physical hazards with marking tape. According to this standard, red signifies fire-related hazards, including the identification of fire protection equipment and containers of flammable liquids, as well as emergency switches, bars, and buttons on hazardous machines. On the other hand, yellow, as stated in 29 CFR 1910.144(a)(3), is designated as the basic color for cautionary purposes and for marking physical hazards such as striking against, stumbling, falling, tripping, and caught-in-between situations.

3) Start with a Floor Marking Plan

A facility floor marking plan should include several key elements to ensure effective implementation and adherence to safety standards:

Purpose and Scope: Define the purpose of the plan, whether it is to enhance workplace safety, improve organization, facilitate workflow, or comply with regulatory requirements. Specify the areas of the facility that will be covered by the plan.

Identification of Hazardous Areas: Identify and mark hazardous areas, such as equipment storage zones, forklift traffic lanes, high-risk machinery, electrical panels, chemical storage areas, and emergency exits with the proper workplace safety signs and tapes. Ensure that markings are clear and easily visible to employees.

Color Codes and Markings: Establish a color code system for floor markings to denote distinct types of hazards or instructions. For example, use red marking tape for fire-related hazards, yellow for caution, green for safe pathways, and blue for equipment or materials storage. Clearly outline the meanings of each color and marking in the plan.

Placement and Size Guidelines: Determine the appropriate placement and size of floor markings based on the specific needs of the facility and the type of hazards being addressed. Ensure that floor signs and tapes are placed where they are easily visible and will not become obscured by machinery, equipment, or foot traffic.

Maintenance Procedures: Define procedures for the regular inspection and maintenance of floor markings to ensure their durability and effectiveness. Specify how often floor tapes and signs should be inspected, who is responsible for maintenance tasks, and what actions should be taken in case of damage or deterioration.

Employee Training: Provide training for employees on the meaning of different floor markings, the importance of adhering to the plan, and how to safely navigate the facility while following the designated pathways and hazard warnings.

Documentation and Review: Document the floor marking plan, including diagrams or maps of marked areas, color code explanations, and maintenance schedules. Regularly review and update the plan as needed to reflect changes in the facility layout, equipment, or safety regulations.

By including these elements in a facility floor signage plan, organizations can help create a safer and more organized work environment for employees while ensuring compliance with workplace safety standards.

Are you ready to implement a floor marking and wayfinding system in your facility? DuraLabel industrial label and sign printers can help print labels and safety signs that fit your facility's unique needs. Learn more about standard industry uses for various colors in the DuraLabel Floor Marking Color Chart.

Floor Marking Tape vs. Traditional Paint

Tape and paint are the most common methods for establishing lanes, boundaries, and walkways. Here is a quick overview of each choice:

Floor marking tape: Floor marking tape requires fewer resources to install than paint. You avoid fumes, spills, drying time, personal protective equipment (PPE) that is commonly required for installing paint-based floor marking. The tape can also offer up to five years of reliability, depending on quality of the tape, traffic, exposure, and conditions.

Traditional paint: Installing floor marking with paint can become arduous. Paint fumes may require employees to wear PPE, ventilation must be accounted for, the lines may take hours to dry, spills are a hazard, and installation requires equipment such as brushes, rollers, and drop cloths. Over time, paint can fade and chip away.

4) Figure out Floor Marking Challenges Unique to Your Facility

Breweries face numerous floor-marking challenges that other industries might not encounter. Here are a few questions to ask while planning a floor marking system:

What Kind of Conditions Should You Prepare For?

Water is a key ingredient in the brewing process, and it plays a role in important clean-up efforts. To that end, brewers need industrial floor marking tape, such as DuraLabel PathFinder TREAD tape that withstands wet conditions; stands up to routine cleaning and sanitization; and helps prevent costly slip, trip, and fall injuries.

Where Can Floor Marking Come in Handy?

Before laying down an inch of tape, audit your facility to see where warehouse floor tape can come in handy. For example, workers may have to navigate between storage tanks, bottling lines, and shipping areas as part of their workflow. This informs the placement of floor signs and tape.

For your facility:

Where are the loading docks? Forklifts and powered trucks transport pallets, kegs, and other equipment in and out of trucks regularly. Hazardous boundaries may also be present around loading docks, as well.

Where are the inventory stacking areas? Floor tapes are very handy for defining inventory areas. Defining specific inventory areas helps you keep aisle clear and is important for workplace safety and a smooth, efficient workflow.

What are the forklift traffic routes? Most large facilities rely heavily on forklifts, so employees should account for their presence and the risks they create. Depending on the size of an outfit, it may make sense to establish pedestrian-only and forklift-only paths and work zones to minimize risks. Employees can also use floor signs and labels to warn employees of forklift hazards.

Does the facility have non-worker traffic? If so, industrial floor marking tape should be installed with pedestrian safety in mind; wayfinding signs, arrows, and clearly defined paths can keep visitors from entering dangerous or restricted areas.

How do workers move around the facility? Keep typical workflow in mind when outlining paths and providing navigational aids. Think about their movement between various tasks, storage areas, equipment operating zones, and product transportation routes. You might consider PathFinder anti-slip tape, suitable for heavy foot traffic where large crowds gather.

5) Get the Floor Marking Tools to Keep Workers Safe

DuraLabel offers a variety of tools and resources to help establish and maintain a floor signage and wayfinding system, no matter the size of its operation. DuraLabel PathFinder tapes can help improve safety and increase efficiency in warehouses and workspaces of all sizes. Numerous colors and materials are available to meet a facility's unique needs. Get started with floor marking today using our free Floor Marking Instant Action Guide.

The free Floor Marking Instant Action Guide helps set up and maintain an effective floor signage system. The guide helps employers minimize slip-and-fall injuries, keep workers safe with glowing pathways in power outages, and choose the best floor marking method for their facility. Give us a call today at 1-888-326-9244 and one of our experts will guide you through the process.

Want to learn more about 5S? The 5S Instant Action Guide can help create a plan and set standards, as well as optimize safety and efficiency in the workplace.

Read Next:

RELATED RESOURCES

Reinforce Safety in Cleanrooms with Floor Tape and More

The typical construction costs for building an ISO 8 to ISO 7 cleanroom can range from $250 to $1,500 per ...

Read

Five Ways Floor Marking Can Solve Common Problems

What Problems Does Floor Marking Address? Floor marking is the process of using tapes, paints, or other ...

Read

Tips for Choosing the Optimal Floor Marking Tape

Industrial floor marking tape is an investment in safety that needs to last to achieve maximum effect. To ...

Read.png)