Improving Mine Rescue Response with OSHA Signs

03

February,

2023

3 MINUTE READ

Using OSHA Signs to Improve the Mine Rescue Response

Although mine rescue response gear, training, and techniques have been improved over the past century, you can never be too prepared for an emergency. Miners need the tools to survive during a disaster. This is where the Occupational Safety and Health Administration (OSHA) steps in. What does OSHA do? OSHA ensures workplace safety by setting and enforcing standards, including those related to signage and labeling requirements. To this end, underground mine safety teams can help to improve mine rescue response by clearly identifying escape routes, placing rescue stations in key locations, and by ensuring there is adequate ventilation.

But how can a mine rescue response better mark things like escape routes and rescue stations? OSHA signs. By strategically placing signs that meet OSHA labeling requirements throughout the mine, rescue teams can swiftly navigate the complex underground environment, locate crucial equipment, and communicate vital safety information, ultimately streamlining the rescue process and enhancing overall response efficiency.

Improving Escape Routes with OSHA Signs

Improving Escape Routes with OSHA Signs

When a fire or other disaster happens, miners need to be able to quickly follow their escape route. Safety professionals can improve their response to disasters and keep miners safe by:

- Training miners to immediately follow escape routes during an emergency

- Using emergency signals like flashing lights and alarms to signal specific types of emergencies (fire, explosion, and so on)

- Creating set responses for specific emergencies (during a fire, all miners immediately go to their designated rescue station)

- Implementing OSHA signs and labels for effective communication

- Using a highly reflective prismatic tape to mark escape routes

- Ensuring escape routes are free of obstructions

MSHA's 75.380 requires all escape routes to the surface to be marked every 25 feet with reflective tape. Doing this ensures miners will find their way, even in low-light conditions. Further, marking routes to rescue stations and labeling the stations will help miners quickly identify where they are going as well as when they arrive at their destination.

From creating safety signs to printing OSHA labels, the DuraLabel Kodiak Max Industrial Sign and Label Print System assures you have everything you need to boost miners' safety with the appropriate signage.

Using Rescue Stations

Another way mines can improve their rescue response is by ensuring that they have enough rescue stations (refuge alternatives). As the following examples show, these stations prove that they keep miners safe in the aftermath of explosions and fires:

April 6, 2015: In a northern Manitoba nickel mine, eight miners took refuge in an underground safe room after a fire broke out. No injuries were reported.

January 28, 2013: A fire at Mosaic's K2 potash mine near Esterhazy, Saskatchewan sent 318 miners to underground refuge stations where they waited for hours as emergency crews put out the blaze and the heavy smoke cleared. There were no injuries.

September 25, 2012: Miners spent a day in an underground refuge station after a fire started at PotashCorp's Rocanville Saskatoon mine. According to news reports, there were 29 people underground when the fire broke out, and nine of them were lifted out. When the fire alarm sounded, everyone immediately headed to four separate refuge stations scattered throughout the facility. All miners escaped injury.

Each of these examples highlights the importance of having rescue stations and training miners to immediately take shelter during an emergency. Most stations are equipped with at least three days of food and water and have redundant air systems with proper pipe labeling to ensure miners remain safe.

Optimizing Mine Ventilation with Proper OSHA Signs

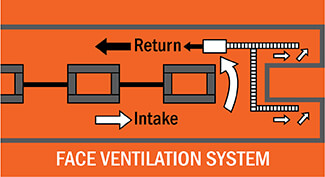

Miners can't be rescued until the smoke clears and the tunnels cool. Bill Cooper, PotashCorp's manager of public affairs, sheds some light on the importance of ventilation: "It's a matter of cooling the area down and ventilating the air? The air quality's got to be at a point where it's safe to take people to the surface." With miles of tunnels, the mine's ventilation system needs to clear out the smoke and heat before people can be brought to the surface. It's no surprise then that good ventilation makes the difference between a timely or drawn-out rescue.

MSHA requires mines to have a Mine Ventilation Plan to control dust and dilute methane levels (75.370). The plan must be reviewed every six months, consisting of:

- A re-examination of the plan

- An in-person observation of the system

- An inspection of the bleeder system

- An inspection of a portion of the ventilated areas

- An inspection of a portion of the ventilation controls and construction

- A review of historical methane levels, ignition, citations, petitions, respirable dust, diesel equipment, escapeways, comments from miners, and the active mine file

- A review of mine's map

Incorporating OSHA signs and labels throughout the mine can enhance safety communication and assist miners in navigating the facility during emergencies, further ensuring their safety. Overall, taking the necessary measures and following all MSHA standards will help to ensure that your mine's ventilation system will not only reduce respirable dust and methane levels but also clear out the smoke and cool down the mine after a fire.

Improve your mine's safety and keep workers safe with DuraLabel's free Mine Safety Best Practice Guide. This guide helps demonstrate how you can increase safety, improve efficiency, and reduce costs using lean manufacturing. Teach your workforce to proactively tackle and solve problems, identify safety issues, and ensure your mine is as safe as possible. Download today.

| Best Practice Guide for Mine Safety Free guide describes MSHA's rules for mine safety and helps improve workplaces. |

Read Next:

RELATED RESOURCES

Creating Compliant OSHA Signs: Tips and Best Practices

Creating compliant OSHA safety signs is a crucial element in the overarching mission of fostering a safe and ...

Read

OSHA General Duty Clause

What is the OSHA General Duty Clause? OSHA's General Duty Clause, in its entirety, reads: "Each employer ...

Read

Prevent Arc Flash with LO/TO and OSHA Signs

The Role of LO/TO and OSHA Signs in Safeguarding Against Arc Flash In the realm of electrical safety, the ...

Read.png)