June 2016 GHS Timetable

03

February,

2023

4 MINUTE READ

With its publication in the Federal Register on March 26, 2012, OSHA's rewritten Hazard Communication Standard (HCS) established its alignment with the Globally Harmonized System (GHS) of Classification and Labeling of Chemicals in the United States. This resulted in changes in:

- Chemical hazard classification

- Labeling of chemicals

- Safety Data Sheets (SDS) which are replacing Material Safety Data Sheets (MSDS)

- Training of employees

The new system is often called HazCom 2012, to distinguish it from the previous version of the HCS.

What is the June 2016 GHS Timetable?

To allow American industries to transition to the new system effectively, OSHA established a timetable. This schedule provided time for training employees, for acquiring new label printing capabilities, and for using up existing stocks of chemicals which already had been labeled under the old system. The timetable stretched from the rules's publication in 2012 until June 2016.

- December 1, 2013 ? All employees who use, handle, or store chemicals needed to have been trained on the new label elements and safety data sheet (SDS) format.

- June 1, 2015 ? All chemical manufacturers, importers, and distributors must be in compliance with the 2012 OSHA HCS requirements. This includes classification of chemicals, preparation of safety data sheets, and preparing GHS labels.

- December 1, 2015 ? The grace period ends for shipping existing inventory that had older labels. All shipments of chemicals must have the new GHS compliant labels.

- June 1, 2016 ? All employers must be in full compliance with the new HCS. This includes having updated their written workplace hazard communication program to incorporate the new GHS requirements. The training of employees on their new workplace hazard communication program must also be completed.

What Needs to be Done?

OSHA listed six steps for being in full compliance with the revised HCS.

1. Identify Responsible Staff

Responsibility for implementation of hazard communication should be assigned to a specific person. That person should then identify and coordinate those who are responsible for completing specific activities, and should be responsible for ensuring they are familiar with the updated rules.

2. Prepare and Implement a Written Hazard Communication Program

The Hazard Communication Program is a written plan describing how hazard communication will be accomplished in a specific workplace. In general, each workplace must have a written plan.

This plan does not have to be complicated or lengthy, as long as it provides for all employees to be fully aware of the chemical hazards in their workplace. Many trade associations or other industry groups have sample programs available that are tailored specifically to their industries. If you base your program on a generic example, be sure it has been modified to accurately reflect the chemicals you use in your workplace, the physical arrangement of your facility, and the type of work you do.

One of the key requirements for your plan is that it must include a list of the hazardous chemicals known to be present in your workplace. This list makes it easier to ensure you have all of the necessary safety data sheets and completed the required labeling.

Your hazard communication program should also cover the procedures for informing employees about hazards associated with non-routine tasks. For example, vessels or tanks may be cleaned infrequently, so workers may not be familiar with the cleaning procedures. Those doing the cleaning will need to be trained so they know about the hazards associated with the materials the vessels and tanks held, and how they can protect themselves from those hazards.

3. Ensure Containers Are Labeled

Chemicals should arrive at your facility in containers that have GHS-aligned labels. Those labels should be kept in place. If they are damaged, they will need to be replaced. Any containers that leave your workplace must be similarly labeled. Most workplace containers ? those that never leave your workplace ? must be labeled as well. A container holding a hazardous material must, at a minimum, have a label with the product identifier and general information about the hazards associated with that material. In all cases your employees must be fully informed about chemical hazards, although some information may be supplied through means other than labels.

OSHA states that your hazard communication program should provide the following information about container labeling:

- For workplace chemical containers:

- Identify the person responsible for ensuring all workplace containers are labeled;

- Provide a description of the system to be used for labeling workplace containers;

- When applicable, describe alternatives to labeling of workplace containers;

- For chemical containers shipped from your facility:

- Identify the person who is responsible for ensuring the containers are properly labeled;

- Describe the labeling system used for making GHS labels for shipments from your facility;

- Establish procedures for reviewing and updating labeling information.

4. Maintain Safety Data Sheets (SDSs)

You must have readily available safety data sheets for every hazardous chemical in your workplace. They are the source for detailed information about the hazards of a chemical.

Have SDSs readily available. Having copies in binders placed around the workplace is one example. Keep in mind that employees who work in the field also need ready access to SDSs. This may mean keeping SDSs in the cabs of trucks, or in mobile offices.

5. Inform and Train Employees

It is the employer's responsibility to train all employees. OSHA states:

Paragraph (h) of the HCS requires that employers train employees on the hazardous chemicals in their work area before their initial assignment and when new hazards are introduced into the work area, and this training must be conducted in a manner and language that employees can understand. Workers must understand they are exposed to hazardous chemicals. They must know that labels and safety data sheets can provide them with information on the hazards of a chemical, and these items should be consulted when needed. In addition, workers must have a general understanding of what information is provided on labels and SDSs, and how to access them. They must also be aware of the protective measures available in their workplace, how to use or implement these measures, and whom they should contact if an issue arises.

6. Evaluate Your Program

Your written hazard communication program should be reviewed periodically, and revised if changes are necessary due to changes in the workplace, the use of new chemicals, changes in work procedures, or any other changes that might result in exposure to chemical hazards. Your hazard communication program must remain current and applicable to the existing conditions in your facility.

Master GHS compliance with our free GHS Labeling guide. Download it below.

RELATED RESOURCES

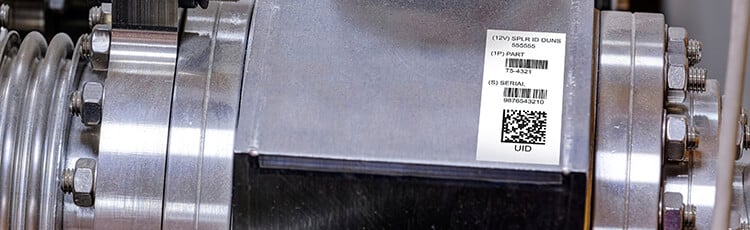

Achieve IUID Compliance with Thermal Transfer Printing

If your company works with the United States Department of Defense (DoD), you must comply with military ...

Read

Red Diamonds on HazCom 2012 Labels

Six elements of information must be present on the typical HazCom 2012 chemical label, as listed in OSHA's ...

Read

Hazard Pictograms

What are Hazard Pictograms? Hazard pictograms are graphic symbols used on GHS labels to communicate ...

Read.png)