OSHA Safety Management Plan

03

February,

2023

4 MINUTE READ

What is an OSHA Safety Plan?

An OSHA Safety Plan is a written plan that describes the potential hazards in the workplace, and the company policies, controls, and work practices used to minimize those hazards. Although some states do require an "OSHA Plan," OSHA does not require a general safety plan. However, you may have specific workplace conditions or chemicals present that do require an OSHA Safety Plan.

Some of the conditions, activities, and substances that require a written OSHA Safety Management Plan include:

- Hazard Communication (29 CFR 1910.1200(e)) ? this requires a written chemical worker right-to-know safety plan

- HAZWOPER Safety and Health Plan (29 CFR 1910.120(b))

- Emergency Action Plan and Fire Prevention Plan (29 CFR 1910.38 and 29 CFR 1910.39)

- Bloodborne Pathogens Exposure Control Plan (29 CFR 1910.1030(c))

- If you have permit-required confined spaces, lockout/tagout (LO/TO) management, respirator use, work requiring fall protection, or if there are excavations, you will need to have an OSHA Safety Plan.

Even if your workplace does not have conditions requiring an OSHA Safety Plan, OSHA does require that employees and their supervisors be trained in the specific hazards and control measures associated with their assigned tasks. A written OSHA Safety Plan is a valuable tool in providing this training.

An OSHA Safety Plan generally has four elements:

- Management Leadership and Employee Involvement

- Worksite Analysis

- Hazard Prevention and Control

- Training

Management Leadership and Employee Involvement

Both management and employee involvement is needed when creating a safety plan. If employees are involved in identifying and resolving safety and health problems, they will bring their unique insights and energy to achieving the goals and objectives of your safety plan. Employees are the most valuable assets a company has. Their safety, health, and goodwill are essential to the success of a business. Having them work with management in protecting their safety and health not only helps to keep them healthy-it makes management's job easier.

Both management and employee involvement is needed when creating a safety plan. If employees are involved in identifying and resolving safety and health problems, they will bring their unique insights and energy to achieving the goals and objectives of your safety plan. Employees are the most valuable assets a company has. Their safety, health, and goodwill are essential to the success of a business. Having them work with management in protecting their safety and health not only helps to keep them healthy-it makes management's job easier.

Here are some actions to consider when creating an OSHA Safety Plan:

- Post the company policy on worker safety and health next to the OSHA Workplace Poster where all employees can see it.

- Hold a meeting with all employees to discuss objectives for safety and health.

- Management should ensure that support is visible by getting personally involved in the activities that are part of your safety and health program. For example, management should review all inspection and accident reports and ensure that follow-up occurs when needed.

- Ensure that managers and supervisors follow all safety requirements that apply to all employees, even if only in an area briefly.

- Take advantage of employees' specialized knowledge and encourage them to buy into the program by having them make inspections, conduct safety training, or investigate accidents.

- Make clear assignments of responsibility for every part of the OSHA Safety Plan, and make sure everyone understands them. The more people who are involved, the better.

- Give those with safety and health responsibility enough people, time, training, money, and authority to get the job done.

- At least once a year, review what has been accomplished.

- Institute an accountability system where all personnel will be held accountable for not following work rules designed to promote workplace safety and health.

OSHA Safety Plan Worksite Analysis

In creating an OSHA Safety Plan, you need to know what workplace hazards exist and what is necessary to keep workers safe.

Here are some actions to consider:

- Request a consultation visit from your state on-site Consultation Program covering both safety and health to get a full survey of the hazards that exist in your workplace and those that could develop.

- Review conditions and get advice when changes are made to procedures or equipment. Find ways to keep current on newly recognized hazards in your industry.

- Periodically review with employees each job, analyzing it step-by-step to see if there are any hidden hazards in the equipment or procedures.

- Set up a self-inspection system to check hazard controls and evaluate any new hazards.

- Encourage employees to alert management when they see things that look dangerous or out of place.

- Learn how to conduct a thorough investigation when things go wrong.

- Review several years of injury or illness records to identify patterns that can help devise strategies to improve your safety and health program. Periodically review several months of experience to determine if any new patterns are developing.

Hazard Prevention and Control With an OSHA Safety Management Plan

Once existing and potential hazards (hazard identification) have been identified, the next step is to implement the systems that prevent or control those hazards. Whenever possible, hazards should be eliminated. Sometimes that can be done through the substitution of less toxic material or engineering controls. When hazards cannot be eliminated, systems should be established to control them.

Here are some actions to consider:

- Set up safe work procedures based on an analysis of the hazards in your workplace and ensure that employees understand and follow them.

- Be ready to enforce the rules for safe work procedures. Ask your employees to help you establish a disciplinary system that will be fair and understood by everyone.

- Where necessary, ensure that personal protective equipment (PPE) is used and that your employees know why they need it, how to use it, and how to maintain it.

- Plan for emergencies, including fire and natural disasters. Conduct drills to ensure that all employees know what to do under stressful conditions.

- Develop an emergency medical procedure to handle injuries, transport ill or injured workers, and notify medical facilities. Posting emergency numbers is a good idea.

- Survey the medical facilities near your place of business and make arrangements for them to handle routine and emergency cases. Cooperative agreements may be possible with nearby larger workplaces that have on-site medical personnel and/or facilities.

- Ensure that your procedure for reporting injuries and illnesses is understood by all employees.

- Perform routine walk-throughs of the worksite to identify hazards and to track identified hazards until they are corrected.

Safety Plan Training for Employees, Supervisors, and Managers

An effective OSHA Safety Plan includes comprehensive safety training for everyone: management, workers, contractors, and even visitors.

Each employee needs to know that:

- No employee is expected to undertake a job until he or she has received job instructions on how to do it properly and is authorized to perform that job. Also,

- No employee should undertake a job that appears unsafe.

Here are some actions to consider:

- Make sure employees are trained on every potential hazard that they could be exposed to and how to protect themselves. Then verify that they understand what they were taught.

- Pay particular attention to new employees and employees who are conducting new tasks.

- Train supervisors to understand all the hazards faced by employees and how to reinforce training with quick reminders and refreshers, or with disciplinary action if necessary.

- Make sure that your top management staff understands their safety and health responsibilities and how to hold subordinate supervisory employees accountable for theirs.

Need help putting an OSHA Safety Plan together? Duralabel can provide Safety Assessment Services for you.

RELATED RESOURCES

IIPP (Injury and Illness Prevention Programs)

An injury and illness prevention program (IIPP), has been established to help employers identify and fix ...

Read

Risk Management with ISO 31000

Running a business involves risk. Risk cannot be avoided, but it can be managed. ISO 31000 provides ...

Read

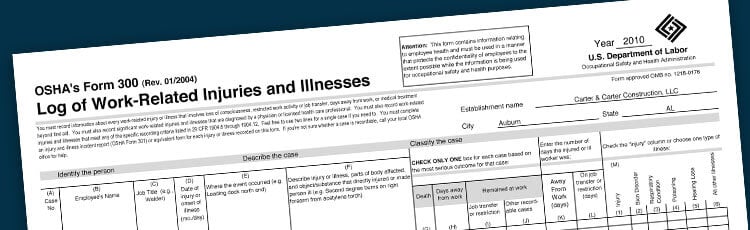

What is an OSHA 300 Log?and do I have to use one?

If your workplace has more than 10 employees at any time throughout the calendar year, and is non-exempt, ...

Read.png)