3 Smart Ways to Improve Kanban

03

February,

2023

2 MINUTE READ

Manufacturing, shipping, receiving, storage ? these processes are as efficient as a business' culture allows. When there is pressing demand, such as for personal protective equipment at medical facilities on the front lines of the coronavirus, controlling inventory can go haywire. The situation also puts stress on manufacturers as they struggle to make up for the deficit. While productivity might be functional, any company benefits from improvement especially during a time when workers are working from a variety of environments. Employing the disciplines of lean, including Kanban, turns regular business into a more efficient lean manufacturing machine. Yet, like any lean program, if Kanban is not sustained, things can go awry.

Keep the Flow

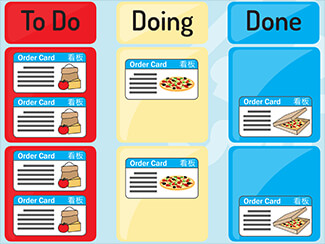

Kanban is a visual logistics control system based on customer demand. Kanban uses visuals, such as diagrams, charts, note cards, and statistics to show the workflow process and tracks orders from start to finish. It's intended to be easy for all workers to understand and keep in order. Using visual communication and inventory management this way offers greater efficiency than a traditional inventory pull system. Kanban helps any team become more agile and increases the manageability of production.

"Everyone should already know exactly who's working on what ? at any given time," wrote Janet Mesh at Trello, a digital lean project management company. "If this sounds like organizational bliss, then it's time your team adopts the Kanban method."

Ginny Womelsdorf, a small business owner in New York, sings the praises of Kanban. She and her staff use Kanban to help recycle and limit waste in the workplace, such as batteries, lightbulbs, and other hazardous materials.

"Employees were definitely into it," she said. "It was helpful getting a little extra cash back, which was used for buying lunches for employees ? amazing how food motivates people. We did have designated containers for everything. However, we try to limit any excess inventory and only have a minimum quantity on hand of these items in-house. We used a Kanban card ordering system to keep inventory at bay."

Kanban isn't a once and done form of lean management. It is a component that needs careful consideration in project planning, inventory tracking, and execution. Lean management staff should stay on top of their facility's Kanban by documenting and taking notes from each step and reviewing the data.

Fix Kanban Issues

A Kanban board, whether physical or digital, allows everyone on a work team to view what to do. It also helps workers collaborate and update. When stressors come into play and workflow no longer flows, or there are product shortages, a Kanban system needs revisiting. Production might not be adjusting to meet demand. Here are several tips to improve a visual board to maximize efficiency and sustain functionality.

A Kanban board, whether physical or digital, allows everyone on a work team to view what to do. It also helps workers collaborate and update. When stressors come into play and workflow no longer flows, or there are product shortages, a Kanban system needs revisiting. Production might not be adjusting to meet demand. Here are several tips to improve a visual board to maximize efficiency and sustain functionality.

- Check the steps: Keep the Kanban system in check continuously. Take inventory to ensure all Kanban cards are present, accurate, and meet the needs of the work. Follow the 5S system steps. Having a solid to-do list is a priority. Check the list and review it. Take notes for new activities and to stay on track.

- Measure quality over quantity: Look over the product schedule. Re-evaluate priorities. Make sure to meet production requirements. If there are unrealistic deadlines, this can affect quality and efficiency. Have too much or too little product? Re-evaluate the system and reduce waste.

- Evaluate visuals: Examine the visual cues that help support Kanban in the workplace to ensure they reflect maximized efficiency. Signs, labels, and floor marking provide visual guides to streamline the Kanban process. Check that these tools are in the correct location, are using the right colors and have barcodes. Visual cues should meet the needs of all staff (size, text, language, and symbols).

Kanban can benefit any business. It is a great teamwork tool to keep workplaces productive, flexible, and transparent. Lean managers and staff should revisit their Kanban process, look for ways to improve it, remember why Kanban is in place, and ensure visual cues are functional. This will help streamline production and stem hindrances in Kanban's functionality.

Need a tool to help implement Kanban? Download this free Kanban guide.

RELATED RESOURCES

Start a Workplace Kanban Board

Efficiency is a necessity in business and life. Increasing efficiency saves time and money, which in turn ...

Read

Improving Disability and Inclusion Efforts in Manufacturing

Does your workplace aim to be more inclusive? Providing opportunities for all is not so difficult and ...

Read

What Safety Pros Learned in 2020 for 2021

In what has been a challenging year for businesses and their staff has also been a teacher. Safety leaders ...

Read.png)