4 Things to Do to Meet IEEE 1584-2018 Changes

03

February,

2023

2 MINUTE READ

A lot has changed since 2002. That year gave us the first cell phone in the U.S. to come with a built-in camera, and Apple released its second-generation iPod, with a whopping 20 GB of storage space. It was also the year that the Institute of Electrical and Electronics Engineers (IEEE) published their methods to calculate the arc current, incident energy, and arc flash boundary of a potential arc flash, in the IEEE 1584 standard. For the first time in 16 years, there's been an update to IEEE 1584. It features new equations, methods, formulas, language clarifications, and more.

Next-Level Assessments

Based on 2,000 additional arc flash tests, IEEE 1584-2018 contains information that is important for facilities that are updating their arc flash assessment information. Assessments help convey work and safety information to workers, and help prevent mistakes that can lead to accidents. According to respected power industry publication Electricity Forum, there are five common electrical safety mistakes:

- Not verifying the absence of voltage before beginning work

- Not identifying the arc flash hazard. Be sure to evaluate the electrical hazard risks and implement the appropriate controls

- Lack of personal protective equipment (PPE), or inappropriate selection and/or use of PPE

- Complacency to low voltage hazards (typically 115 to 250 volts)

- Failure to develop and communicate an emergency response plan

Working with energy is serious business, and a shock or arc flash can injure or kill. According to a chart by the Electrical Safety Foundation International using data provided by the Bureau of Labor and Statistics, 156 workers died from exposure to electrical energy in 2016; 15 percent more than in 2015. The utility industry had the highest, followed by the construction industry.

Simple Compliance

OSHA's lockout/tagout standards (in 29 CFR ?1910.147 and ?1910.333) requires employers to develop and use hazardous energy control procedures. However, failure to use LO/TO is one of the top 10 most frequently cited workplace safety violations every year. Part of OSHA's requirements is the establishment of a written energy control program. Once a facility arc flash assessment is complete, there is more work to be done:

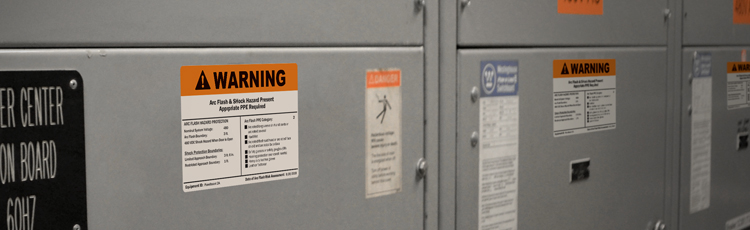

- Ensure arc flash communication is up to date and accurate

- Re-evaluate arc flash and energy training; written policy, while providing workers a refresher on policy

- Update PPE reminders and PPE information

It only takes one electrical incident to produce huge costs for an organization, not only in fines, insurance premiums, and reputation, but also in workers' health and lives. With the right tools, facility managers can easily update visual communication and labels for arc flash for hazard prevention and to help keep workers safe. Informative warning labels are important to help keep workers safe from arc flash hazards. Continually develop safe work procedures, train workers, identify hazards, evaluate risks, plan and document safe work.

Quickly understand the key aspects of arc flash labeling in our free Arc Flash Labeling guide.

RELATED RESOURCES

Communication Tower Safety Involves Many

For 30 years, there has been an increase in communication towers for 911 services, cell phones, electricity ...

Read

Installing Electrical Safety from the Start

There is no harm in double-checking work for safety, especially after an electrical installation. Here are ...

Read

The Survivor's Guide to Arc Flash Safety

On Thursday, August 12, 2004, electrical contractor Donnie Johnson's day began like any other. However, the ...

Read.png)