Crucial Objectives for Industrial Professionals

03

February,

2023

2 MINUTE READ

An increase in competitive demand, regulatory scrutiny, and ever-tightening production margins are changing the expectations for quality these days. Throw in complications and new challenges from the coronavirus pandemic, and business might feel like 2020 plans are unstable. Workplaces are conducting new risk assessments to meet their safety goals.

"Back in March, we conducted risk assessments at each site, looking at how and where people work, how they interact, and what measures are needed to meet safety standards," carmaker Tesla said in its Getting Back to Work statement. "We will continue to put people back to work in a safe and responsible manner."

Improving Performance

Objectives for performance improvement in the workplace are not solely reliant on safety compliance, but it is part. There are four quality objectives for each industry to master new obstacles and increase efficiency.

Documenting Quality

A survey of lab professionals shows that 73 percent say documenting and maintaining compliance is a top objective. In labs, maintaining compliance, especially chemical safety using safety data sheets, requires paying close attention to requirements that vary by location and can change throughout a product lifecycle. All businesses can afford to follow compliance and improve overall operations. Thoroughly inspect the facility. Document new hazards and changes that need to be made. Identify practical solutions and take the steps that make sense for the facility and the safety of its workers. Need a handy resource to help get this process going? Download this Facility Safety and Identification Workbook.

Cost Reduction

Everyone wants to reduce costs. Does the company lack data to benchmark and improve performance for efficiency and safety? When work processes change or new challenges arise, the risks for inefficiency and injuries increase. Workplaces can see the impact injuries and illnesses have on profits through OSHA's Safety Pays Calculator. Harness data and use it to benefit operations. Avert unnecessary costs through continuous improvement efforts.

Make an Impact

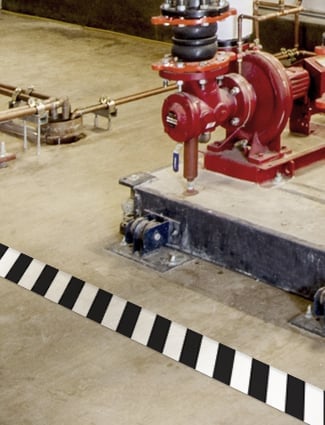

Once a facility conducts its analysis and has solid data to improve economic performance, the results will also benefit manufacturing performance. When critical initiatives are put on the priority list, the results will speak for themselves. Create an action plan that addresses each issue thoroughly and assigns logical controls. Use visual components to reinforce worker understanding of expectations. For example, alert workers to safe working boundaries and proper protocol through signs, labels, and floor marking. Update safety data sheets, emergency plans, and training materials.

Strengthen Culture

Workplace culture is among the hidden elements of a business' success. How does management interact with the front-line workforce? Who has the responsibility of implementing new safety and efficiency actions? Engaging a workforce requires people-centric policies, technology, and leadership practices that empower workers to own their performance and accountability. It also helps to attract quality future talent. Create an open dialogue during safety meetings and ask workers to help contribute ideas to make the workplace more efficient.

Meet Objectives in 2020 and Beyond

By renewing safety objectives, paying attention to data and best practices, and encouraging overall workplace harmony, workplaces can establish stronger quality performance and results. Invest in smart tools to improve product quality, reduce liabilities, and exceed compliance to make an impact on overall performance. Reinforce objectives with visual communication such as signs, labels, and floor marking.

Get a handy guide to core steps for both hazard-based and task-based risk assessments in the EHS Managers Guide.

RELATED RESOURCES

Is Safety the Key to Operational Success?

We talk with EHS pros about how they started in safety management, the importance of their role, and how ...

Read

4 Tips to Strengthen Workplace Culture, Safety

Strong leadership in industry helps worker and workplace safety thrive. Learn why safety culture is ...

Read

130 Years Strong, E.M. Duggan Thrives on Safety

E.M. Duggan is a fifth-generation, family owned mechanical contracting business in Massachusetts. For 130 ...

Read.png)