Facebook Reveals Arc Flash Study, Safety Report

03

February,

2023

2 MINUTE READ

The heat of an arc flash blast can instantly sear through skin and kill from distances, even during the smallest of jobs. So, when two powerful blasts of electricity hotter than the sun's surface amazingly did not injure anyone at a large Facebook data center in 2014 and 2015, the company counted its blessings and jolted into prevention mode.

At a speaking event in October 2017, a Facebook spokesman said that the causes of the arc flash incidents that occurred in 2014 and 2015 revealed electrical housing design flaws. This included the job of tightening of bolts in a busway joint, which was not able to be performed adequately.

Facebook's post-event analysis and response further headed off at least three other potential arc flash incidents, the company's spokesman said. No other details were provided besides noting that "fundamental changes" were made in busway design. Arc flash can cause serious injuries or even death. Proper testing, mitigation, and prediction protection is necessary to maintain efficient safety operations.

"How we talk about failure is important," said James Swensen, Facebook's senior global facilities operations manager. "It's uncomfortable. It's not fun. But if you don't go through that pain, you're not going to get to the lessons learned."

Plan Preventive Maintenance

Arc flash testing is typically completed by companies using the standard five-year update model. However, according to electrical experts at Electrical Engineering Portal, it can be more cost effective as well as an excellent preventative safety measure to proactively test and document those tests as equipment and systems change; such as after replacements of motors or the addition of new panel boards, resizing disconnects and small equipment, and other changes.

In Facebook's case, the company found that the arc flash was caused by several factors such as a cramped space being compact with large amounts of hot energy and areas featuring joint bolts that were not torqued properly. These factors set up a scene that made work to properly tighten joint bolts more difficult. This information was crucial to help Facebook data centers move forward with a preventative safety plan for arc flash and other hazards.

Mitigate Hazards

Exposure to shock, arc flash, and other electrical safety hazards can be caused by a number of factors. Facebook is a huge company with the resources to redesign networks for electrical hazard mitigation. However, industry experts say most companies can apply cautious vigilance, consistent housekeeping, safety mindfulness, and upkeep as excellent deterrents. Some hazard mitigation procedures can include:

- Replacing old or damaged conductor insulation

- Checking for exposed live parts and loose wire connections

- Routinely inspecting and maintaining switches and circuit breakers

- Ensuring cables are appropriate for the voltage being used

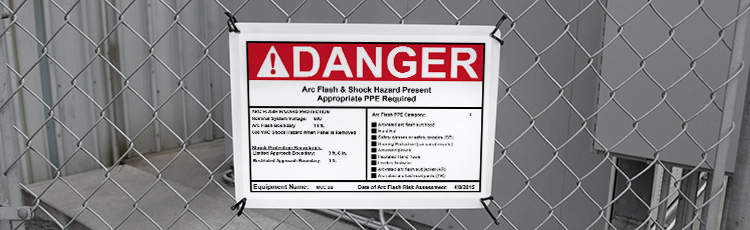

- Updating voltage signs and labels

- Understanding and following critical safety standards for working on electrical equipment, such as NFPA 70E, OSHA's rules for electrical safety and IEEE.

Communicate Electrical Safety Effectively

Signs and labels play an important role in facility management and helps prevent arc flash hazards by communicating necessary safety information to worker to understand jobsite electrical hazards and follow safe practices. When work must be performed on energized equipment, qualified workers need to have the resources to stay safe, such as detailed equipment labels and signs that convey which personal protective equipment (PPE) should be worn. Duralabel has customizable warning labels and signs suitable for any facility. Quickly create new labels on-site and on-demand easily with a DuraLabel industrial label printer.

RELATED RESOURCES

OSHA Clarifies Report Requirements

OSHA overhauled record-keeping updates at the start of 2015. This week OSHA clarified rules which require ...

Read

OSHA Postpones Slips, Trips and Falls Regulation

The final rule is now slated for publication in April. OSHA has postponed reviewing its final rule addressing ...

Read

OSHA Extends Deadline for Reporting Injury, Illness Data

OSHA's Injury Tracking Application (ITA) is accessible online, where employers can provide their 2016 OSHA ...

Read.png)