OSHA Preps for Nationwide Safe + Sound Event

03

February,

2023

3 MINUTE READ

The Occupational Safety and Health Administration's Safe + Sound Week kicks off Aug. 10-16 as part of OSHA's nationwide effort to bring attention to and improve workplace safety. The goal is to raise awareness of the value of workplace safety and rally other workplaces to do the same. Participants earn recognition by sharing information and ideas, events, activities, and social media posts on workplace health and safety.

"Leadership commitment matters and demonstrates workplace safety is a priority," said Acting Assistant Secretary of Labor for Occupational Safety and Health Loren Sweatt. "Safe + Sound Week reminds employers that safety and health programs help businesses save money, eliminate injuries, and most importantly save lives."

During last year's event, more than 2,700 businesses raised awareness about workers' health and safety. As a testament to the importance of enhanced commitment to safety this week, joining OSHA in Safe + Sound Week are some powerful organizations, including the National Safety Council (NSC), the United States Military branches, American Society of Safety Professionals (ASSP), and the National Institute for Occupational Safety and Health (NIOSH).

How to Participate in Safe + Sound Week?

Safe + Sound Week can help organizations jump-start safety and health programs, or energize existing ones. It's also a time to highlight workers' contributions to improving safety and celebrate safety successes. OSHA lists numerous examples that are easy to implement at companies of any size, such as Management Leadership, Worker Participation, and Find and Fix Hazards. While the first two are self-explanatory, the "Find and Fix" category refers to ways that employers and workers can examine their workplaces -- proactively and routinely -- to identify and address hazards before an injury or illness occurs, according to OSHA.

Here are Ways to Participate:

Management Leadership

Positive reinforcement: Become an "Undercover Boss" and take the time to notice when workers meet or exceed safety and health goals, such as reporting close calls and near misses, or attending training that's not mandatory.

As a manager, you can provide positive on-the-spot recognition in person, in employee emails, or internal newsletters for proactive safety measures you encounter each day of Safe + Sound Week. Reinforce your appreciation by giving employees gift certificates or cards to local businesses such as gas stations, grocery stores, and restaurants. You can also gift some company promoting T-shirts, pens, or water bottles as safety reminders that live indefinitely.

Worker Participation

Encourage workers to get involved in thinking day-to-day safety by putting into place a means of measurement. The NSC Employee Safety Perception Survey is complementary by opting into the NSC's program Journey to Safety Excellence?. Having workers participate in the survey is a great way to get people to ask the right questions while also bench-marking the company's safety culture. The NSC survey requires an administrator to organize and send the survey link out to employees via email. Company administrators can then monitor responses and run final reports. Once the administrator gets results, they can benchmark areas needing more safety emphasis, and employees feel like they have a say in safety matters.

Find and Fix Hazards

Find and Fix Hazards

Conduct a Job Hazard Analysis (JHA) by identifying a work activity or process where there may be safety concerns, or ask workers to recommend an area needing more safety attention. Observe the work being done and discuss what might have led to incidents in the past or are susceptible to something going wrong. Identify improvements in the process that could reduce future incidents.

In the same vein, employers can conduct a mock incident investigation, based on a common hazard in the workplace or industry, a past incident that could have been avoided, or a near-miss situation. Ask volunteers to role-play the incident, then have another team of workers and supervisors conduct a mock investigation. Prepare teams by watching a video on what to expect in an OSHA inspection. Include a focus on identifying the root cause of the incident and report the findings. After completing the events or programs, download a certificate and web badge to recognize the organization and workers.

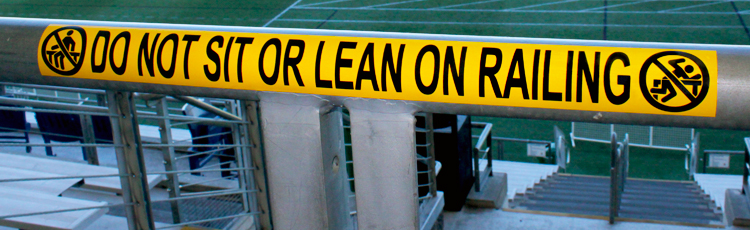

An effective workplace safety plan includes comprehensive safety training for everyone: management, workers, contractors, and even visitors. Workplaces can energize any safety program with the support of OSHA and other organizations in showing a commitment to safety for all. Simple and cost-effective solutions such as signs, labels, and floor marking help convey safety messages to everyone in the workplace. These solutions not only help keep workers safe but they also help improve workplace efficiency.

RELATED RESOURCES

MSHA Increases Conveyor Safety Awareness

The Mine Safety and Health Administration is focusing on conveyor safety after a string of injuries and ...

Read

Lack of Signs at Olympic Games in Rio Adds to Confusion

At the Olympic Games in Rio de Janeiro, 500,000 visitors from more than 200 countries will visit and many ...

Read

OSHA Signs Regulations and Compliance: Everything You Need to Know

OSHA Regulations and Compliance: Everything You Need to Know about OSHA Signs and Labels Navigating the ...

Read.png)