Pipe Marking: A Safety Tool Worth Examining

03

February,

2023

2 MINUTE READ

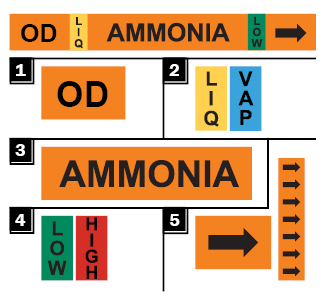

Whether working with old ammonia pipes or new and technologically improved low emission LNG pipes, there are still hazards to be had if a maintenance professional or emergency worker doesn't know what's inside them. It's important to understand pipe marking basics: What direction is the flow? How much pressure? Is that hot water label in the right spot? These questions are anticipated at a facility when individuals come on the scene who are not familiar with the working environment. Dangerous workplace incidents can happen anytime if equipment is not clearly labeled, mislabeled, or not labeled at all.

OSHA's general duty clause supports the ANSI A13.1 pipe marking standard, which serves practical purposes for identification. Facilities that have pipes without labels might be subject to a citation if pipes contain hazardous substances, could cause hazardous conditions, or are part of hazard prevention or emergency response procedures. In general, labeling pipes helps eliminate confusion over pipe contents, which in these instances can result in injury and even death.

Simple Mistakes Can be Costly

Bradford White of Boston has been in HVAC for 43 years. He said he's seen his share of injuries from careless activity around pipes that lacked labeling.

"One involved someone opening a valve to look inside of the end to see what came out," White said. The worker received a face full of 80 psi water that sent his glasses across the room. "It could have bruised his eyeballs. He was lucky."

Another incident, White said, was a process steam line (50 or 60 PSIG steam) without a label. "A worker opened the valve, and when the jet came out, he could not reach the valve handle from that first vantage point, so he went to the other side. Not around back, oh no. He walked right across the stream of steam and suffered second-degree burns across his waist. No amount of signage can compensate for a lack of common sense. But each would have known that there was something in that pipe."

The absence of pipe marking hinders not only worker productivity; it can be detrimental to a workplace's efficiency overall. In some cases, workplace safety extends to environmental safety as well. The EPA pays close attention to facilities that use large amounts of potentially hazardous materials, such as industrial refrigeration systems using anhydrous ammonia. Insufficient labeling of ammonia control valves and piping was among several violations at a meat processing plant during a 2014 inspection by the Environmental Protection Agency. To become successfully compliant with the federal entity, the Massachusetts company ended up spending $300,000 in safety upgrades to improve its hazard communication and more. Hazard communication is the second-most-cited workplace safety violation, according to OSHA.

Plan for Safety

Pipe marking compliments a compliant workplace and can only be beneficial. It helps with facility organization, which also helps improve safety and productivity. Having a pipe marking plan in place ensures consistency in safety management and communication. Labeling pipes takes the guesswork out of identification for maintenance and helps eliminate errors. Workers can then move comfortably from task to task with ease.

Pipe marking compliments a compliant workplace and can only be beneficial. It helps with facility organization, which also helps improve safety and productivity. Having a pipe marking plan in place ensures consistency in safety management and communication. Labeling pipes takes the guesswork out of identification for maintenance and helps eliminate errors. Workers can then move comfortably from task to task with ease.

Whether creating a new facility or upgrading existing pipe marking, streamline the pipe marking process. Create an adequate and thorough pipe labeling plan to minimize disruptions and save time. There are new technological tools such as piping layout software and digital system monitoring that can assist with a variety of pipe marking needs. For quick action, use those tools in combination with premade pipe markers that meet appropriate standards, such as the common ANSI/ASME A13.1 approach. Strengthen pipe marking system communications with tools that are resistant to chemicals and can last in hot or cold environments, such as valve tags, pipe grabber sleeves, and more. Be sure to update labels to reflect changes in the work environment or maintenance protocols.

Never wonder about pipe marking requirements again-legibility and mandatory letter heights, a color guide, label placement examples and more are available in this free pipe marking guide.

RELATED RESOURCES

The Dangers of Abandoned Pipes

Whether a pipe contains chemicals, water, or nothing, it's important to know if it's hazardous. ANSI/ASME ...

Read

Navigating Pipeline Pathways with Directional Pipe Markers

Navigating Pipeline Pathways with Directional Pipe Markers Directional pipe markers are key when it comes to ...

Read

Hunter-Davisson Commands HVAC Safety

Since 1965, Hunter-Davisson has built its reputation for using state-of-the-art tools to handle a variety of ...

Read.png)