- Home

- >

- Resources

- >

- Infographics

- >

- OSHA Improving Worker Safety

OSHA Improving Worker Safety

03

February,

2023

1 MINUTE READ

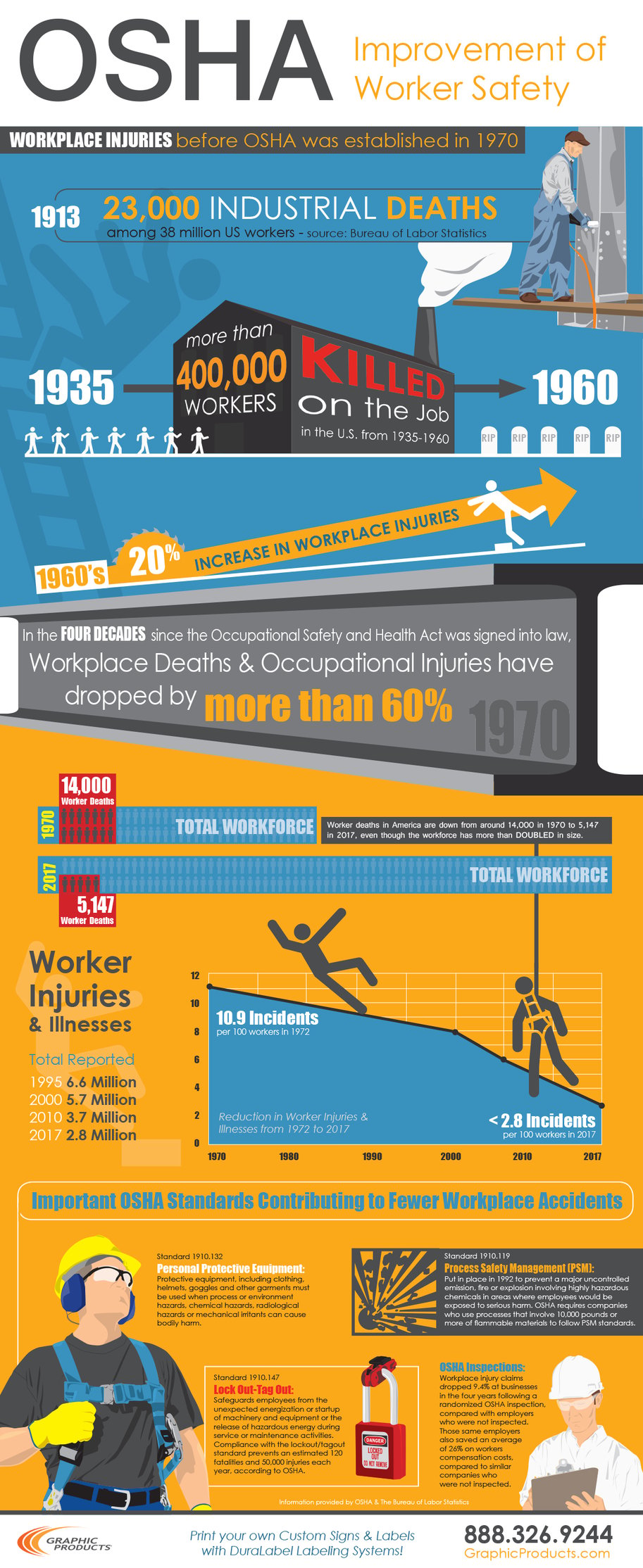

In 1970, OSHA was established to create standards that keep workers safe. Since 1970, workplace accidents and deaths have decreased dramatically, and OSHA continues to strive towards making the workplace as safe as possible. Get a summary of statistics and key OSHA standards that contribute to fewer workplace accidents.

The following is a transcript of the OSHA Improvement of Worker Safety infographic:

OSHA Improvement of Worker Safety

Workplace injuries before OSHA was established in 1970

1913

23,000 industrial deaths. Among 38 million U.S. workers - source: Bureau of Labor Statistics

1935 - 1960

More than 400,000 workers killed on the job in the U.S. from 1935-1960

1960's: 20% increase in workplace injuries

1970

In the four decades since the Occupational Safety and Health Act was signed into law, Workplace Deaths & Occupational Injuries have dropped by more than 60%.

1970: 14,000 worker deaths. Total workforce. Worker deaths in America are down from around 14,000 in 1970 to 5,147 in 2017, even though the workforce has more than DOUBLED in size.

2017: 5,147 worker deaths. Total workforce.

Worker Injuries & Illnesses:

Total Reported

- 1995, 6.6 Million

- 2000, 5.7 Million

- 2010, 3.7 Million

- 2017, 2.8 Million

Reduction in Worker Injuries & Illnesses from 1972 to 2017: 10.9 Incidents per 100 workers in 1972. <2.8 incidents per 100 workers in 2017.

Important OSHA Standards Contributing to Fewer Workplace Accidents

Standard 1910.132-Personal Protective Equipment:

Protective equipment, including clothing, helmets, goggles, and other garments must be used when process or environment hazards, chemical hazards, radiological hazards or mechanical irritants can cause bodily harm.

Standard 1910.119-Process Safety Management (PSM):

Put in place in 1992 to prevent a major uncontrolled emission, fire or explosion involving highly hazardous chemicals in areas where employees would be exposed to serious harm. OSHA requires companies who use processes that involve 10,000 pounds or more of flammable?materials to follow PSM standards.

Standard 1910.147-Lockout-Tagout:

Safeguards employees from the unexpected energization or startup of machinery and equipment or the release of hazardous energy during service or maintenance activities. Compliance with the lockout/tagout standard prevents an estimated 120 fatalities and 50,000 injuries each year, according to OSHA.

OSHA Inspections:

Workplace injury claims dropped 9.4% at businesses in the four years following a randomized OSHA inspection, compared with employers who were not inspected. Those same employers also saved an average of 26% on workers compensation costs, compared to similar companies who were not inspected.

Information provided by OSHA & The Bureau of Labor Statistics.

Print your own custom signs and label with DuraLabel labeling systems.

RELATED RESOURCES

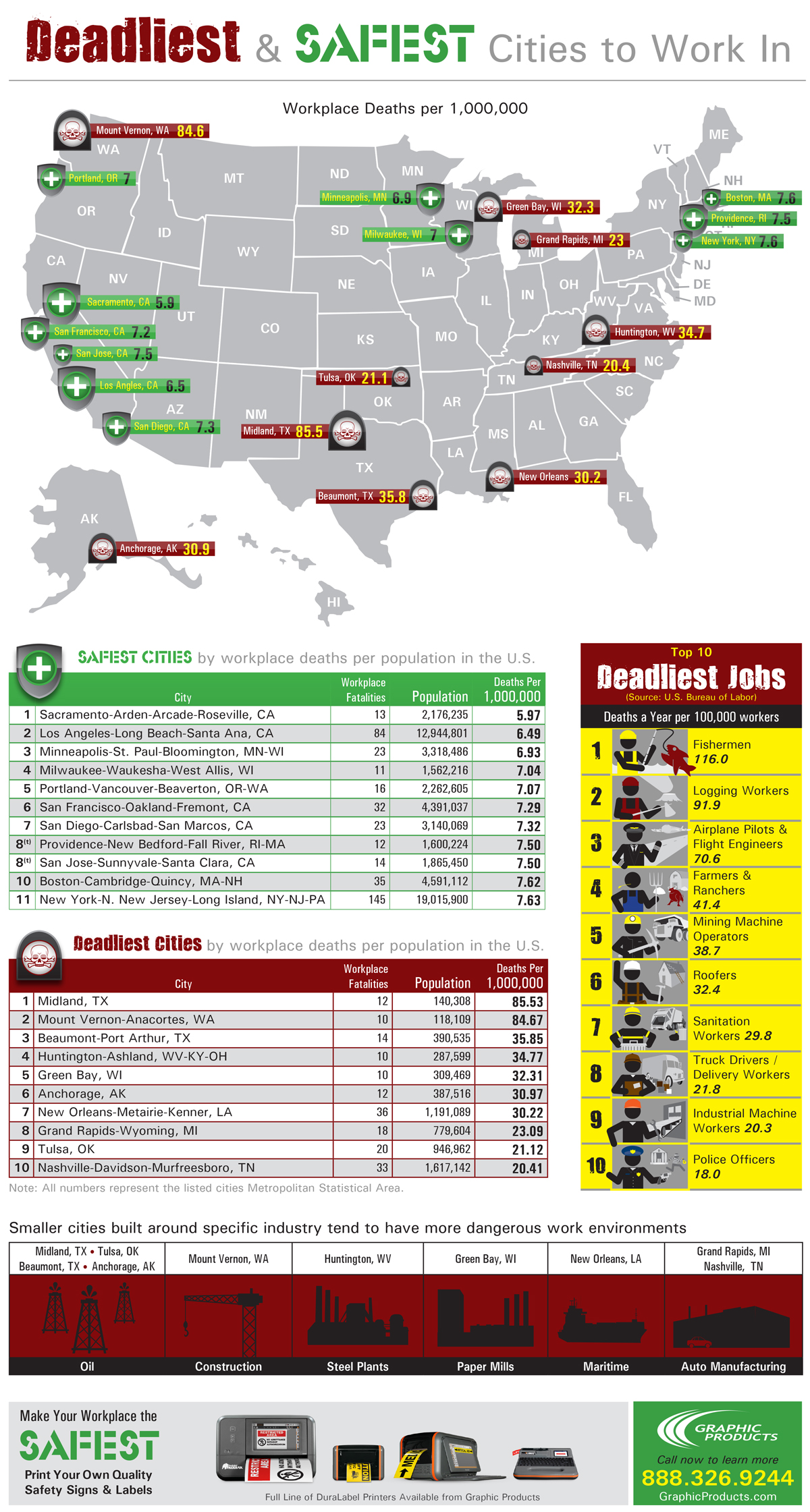

Safest and Deadliest Cities to Work In

Some of the safest cities to work in have the least amount of deaths on the job per capita. Smaller cities in ...

Read

Fire Safety

The Fire Safety infographic showcases some history of fire fighting and the development of the National Fire ...

Read

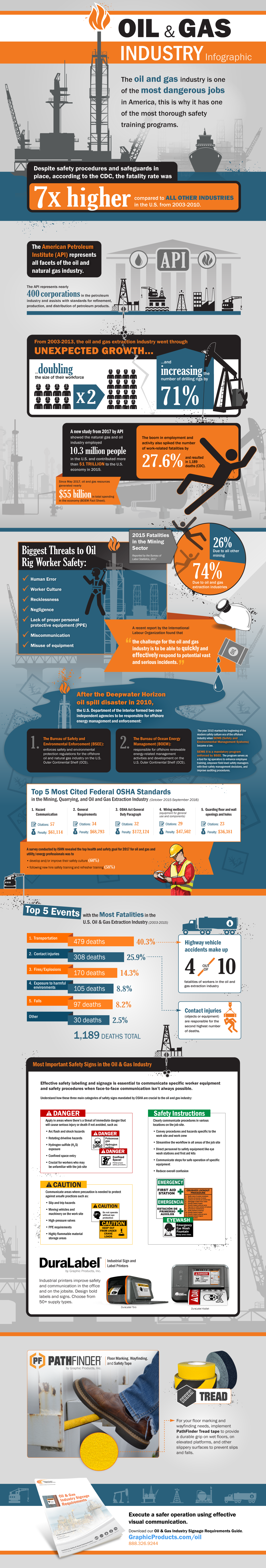

Oil & Gas Industry

The combination of powerful equipment, flammable chemicals, and high pressures cause jobs in the oil and gas ...

Read.png)