- Home

- >

- Resources

- >

- Infographics

- >

- Pillars of TPM

Pillars of TPM

03

February,

2023

1 MINUTE READ

TPM is the concept of self-directed maintenance, wherein machine operators are responsible for the routine maintenance and operations of their machines and equipment.

The following is a transcript of the Pillars of TPM Infographic:

TPM

Increasing productivity through workforce empowerment

1. Autonomous Maintenance

2. Process & Machine Improvement

3. Preventative Maintenance

4. Early Management of New Equipment

5. Process Quality Management

6. Administrative Work

7. Education & Training

8. Safety & Sustained Success

The Three Goals of TPM:

1. Zero unplanned failures

2. Zero product defects

3. Zero accidents

8 Pillars of Activity

Total Productive Maintenance (TPM) increases productivity, efficiency, and safety by empowering operators, team leaders and managers to all play a proactive role in the day-to-day operation and maintenance of their own work areas through 8 pillars of activity.

Pillar 1: Autonomous Maintenance

Operators monitor the condition of their own equipment and work areas.

Pillar 2: Process & Machine Improvement

Team leaders collect information from operators and work areas then prioritize preventative maintenance and improvements.

Pillar 3: Preventative Maintenance

Preventative maintenance tasks and schedules are shared by operators and team leaders.

Pillar 4: Early Management of New Equipment

Based on maintenance reports, team leaders anticipate and plan for parts and equipment lifecycles and report to managers.

Pillar 5: Process Quality Management

Shared responsibility for operation and maintenance encourages quality improvement ideas from all work areas.

Pillar 6: Administrative Work

Managers prioritize data from the previous pillars and share outcomes with team leaders and work areas.

Pillar 7: Education & Training

Continuous improvement includes operator and work area education and training which improves morale, retention, and efficiency.

Pillar 8: Safety & Sustained Success

Facility-wide safety is prioritized which positively impacts sustained success of the TPM program.

For a FREE Best Practice Guide to Total Productive Maintenance (TPM) visit: GraphicProducts.com

RELATED RESOURCES

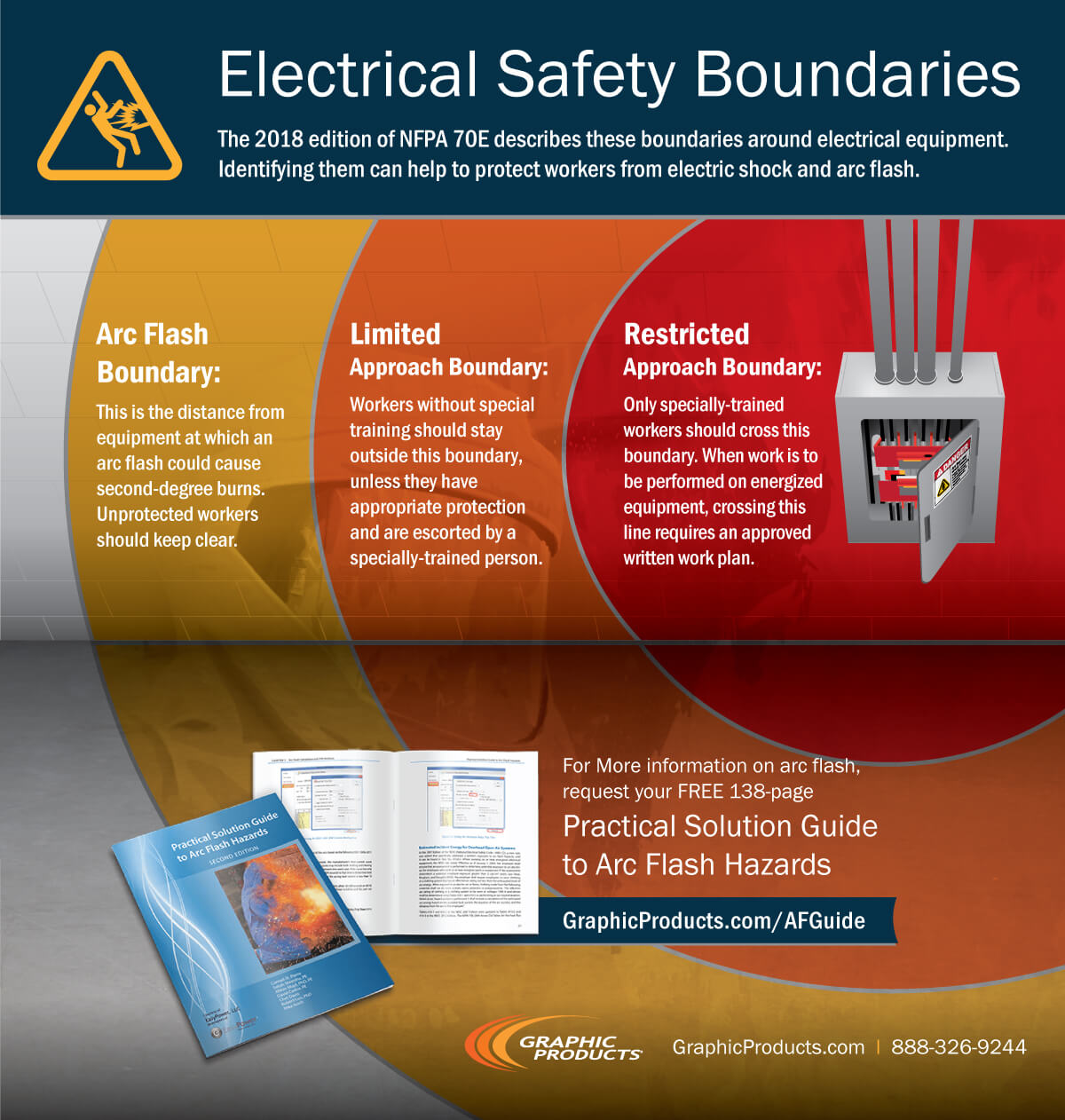

Electrical Safety Boundaries

The National Fire Protection Association (NFPA) recommends a series of protective boundaries around live ...

Read

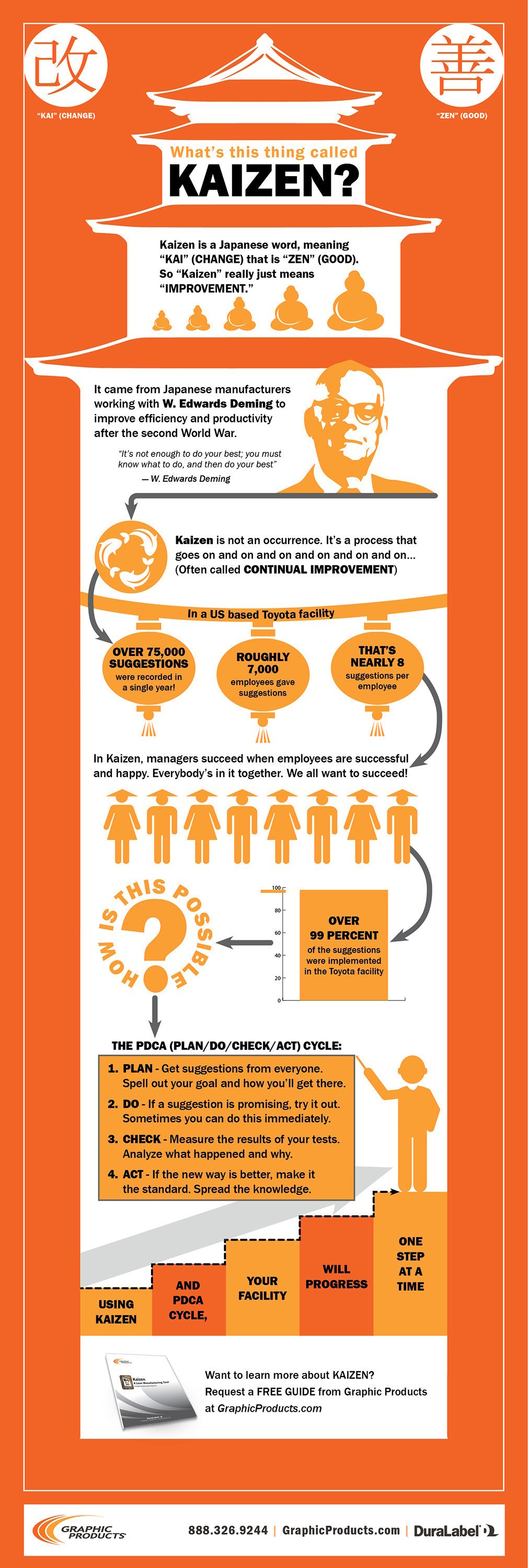

Kaizen

Kaizen focuses on applying small, daily changes that result in major improvements over time. Unlike many ...

Read

Job Hazard Analysis

Everyone wants a safer workplace, but it's hard to make real change in a facility without a clear process. ...

Read.png)