Resource Navigation

Are Arc Flash Injury Rates on the Rise?

03

February,

2023

2 MINUTE READ

Electrical work is one of the most dangerous tasks, but a necessary occupation as global energy needs increase. When working with power, an injury or death can occur in a fraction of a second from an electrical blast powerful enough to incinerate the human body. Eliminating electrical hazards should be a company's first priority, and while personal protective equipment has drastically improved over the past few years, it still should be the last line of defense. Even as much as some companies and workers prepare, the dangers of arc flash are always present.

Shocking Statistics

With all the information available over the years on arc flash, the statistical numbers on workplace injuries and death from hazardous energy are astounding. There were 154 American deaths from exposure to electricity in 2016, according to the Bureau of Labor and Statistics: a 15% increase from 2015. In the power generation industry, the number of non-fatal electrical injuries rose to 2,480 in 2015, the highest since 2009.

Consistently on the Occupational Safety and Health Administration's top 10 list, lockout/tagout citations have gone from the bottom of the list to a steady presence at number 5. LO/TO citations saw an increase of 2% from 2017 with 2,944 in 2018. LO/TO is used for a variety of safety applications, and can be the most effective approach for arc flash protection.

In August, two employees suffered serious burns after enduring an arc flash at a power generation facility in Tennessee. Neither worker was given any pre-work briefings on proper energy controls. They also were not wearing personal protective equipment. The company was cited for several violations and faces fines of $71,600 by OSHA for exposing employees to electric shock hazards.

"These serious injuries could have been prevented if the company had implemented effective work practices to reduce the risk of electric shock hazards," said William Cochran, an OSHA representative in Tennessee.

Jolt Workplace Safety Practices

Modern technologies are helping to design out hazards in the power generation industry among others. However, even with new technology, hazards still remain. Workplaces should implement electrical safety plans, and maintain a high standard of electrical safety using NFPA 70E. Remind workers to wear the appropriate PPE for the task and to use two other important electrical safety practices that should be performed together:

- Power it down: Shut off the power. An arc flash cannot occur if there is no electricity. Do not allow potential for residual electrical energy to accumulate.

- Lock it out: Lockout/tagout is a multi-step process. After powering down machinery and other devices, maintenance can only begin once the machine has a secured lock and a service tag. This isolates workers from electrical dangers and forces workers to pay attention to the maintenance procedures that are needed for optimum safety.

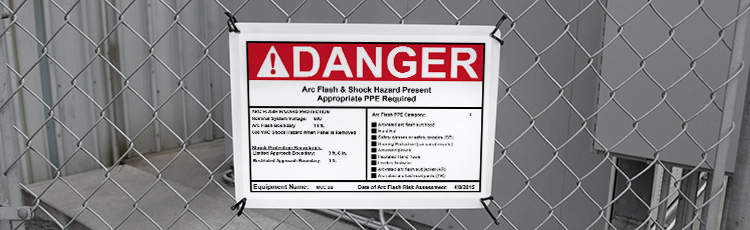

Workers can avoid common and life-threatening injuries by addressing all risks and hazards, and by making safety a top priority. Workplaces should set standard maintenance practices ahead of time. Remind workers of that policy before they begin an electrical maintenance task. Keep workplace communication current and where workers can easily read them, such as maintenance instructions and industrial control panel labels.

RELATED RESOURCES

Strategies for a Confident Supply Chain System

Today's supply chain systems are streamlining everything, from software to safety programs, for maximized ...

Read

OSHA and ACC Unite for Chemical Safety

Working along with the American Chemistry Council, OSHA has begun a campaign on diisocyanate awareness and ...

Read

Facebook Reveals Arc Flash Study, Safety Report

Facebook recently spoke up about two arc flash incidents at one of its data centers. Arc flash can cause ...

Read.png)