- Home

- >

- Resources

DuraLabel Resources

Find industry-specific solutions and practical resources to get the job done. Explore featured content for insights on optimizing workflows, boosting productivity, and ensuring workplace safety.

Applications

Free Guides

DuraLabel Guide to Sign & Label Supplies

Download the DuraLabel Guide to Sign and Label supplies to find durable labeling solutions, ensure compliance, and improve workplace safety with expert tips.

Download

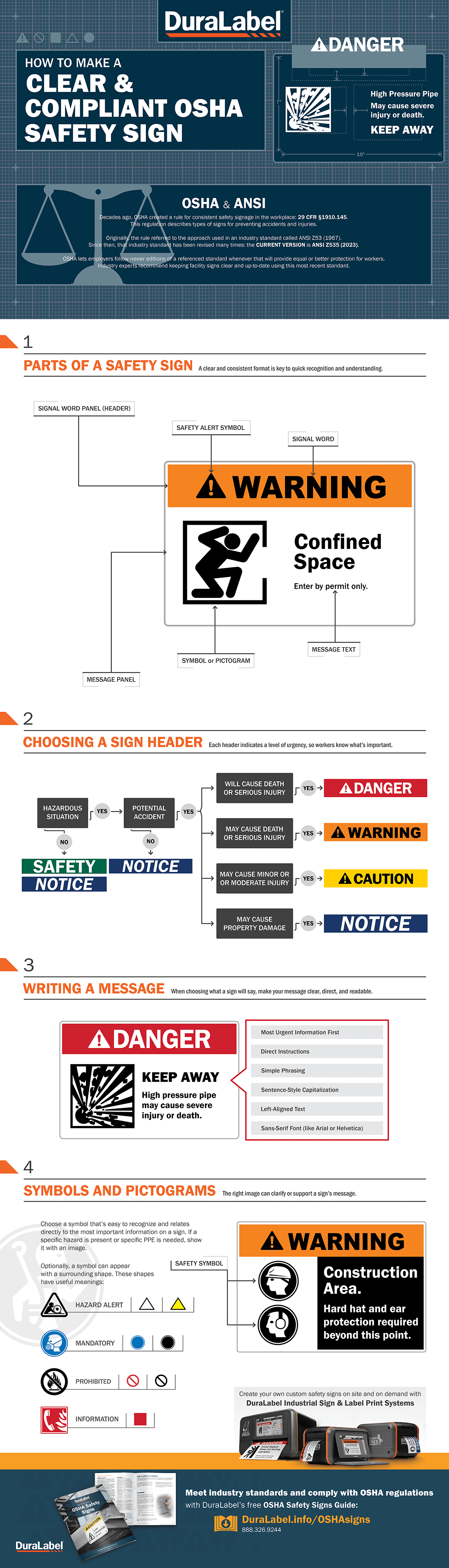

OSHA Signage Quick Start Guide

Learn practical tips on creating compliant safety signs and improving facility safety with DuraLabel's free OSHA Signage Quick Start Guide. Download now!

Download

Kodiak Max Buyer's Guide

Discover the DuraLabel Kodiak Max. Learn how this industrial labeling system simplifies compliance, boosts safety, and enhances facility efficiency.

Download

Toro Max Buyer's Guide

Discover the benefits of the DuraLabel Toro Max in our free Buyers Guide. Learn how this mobile labeling system boosts efficiency and safety in any industry.

Download

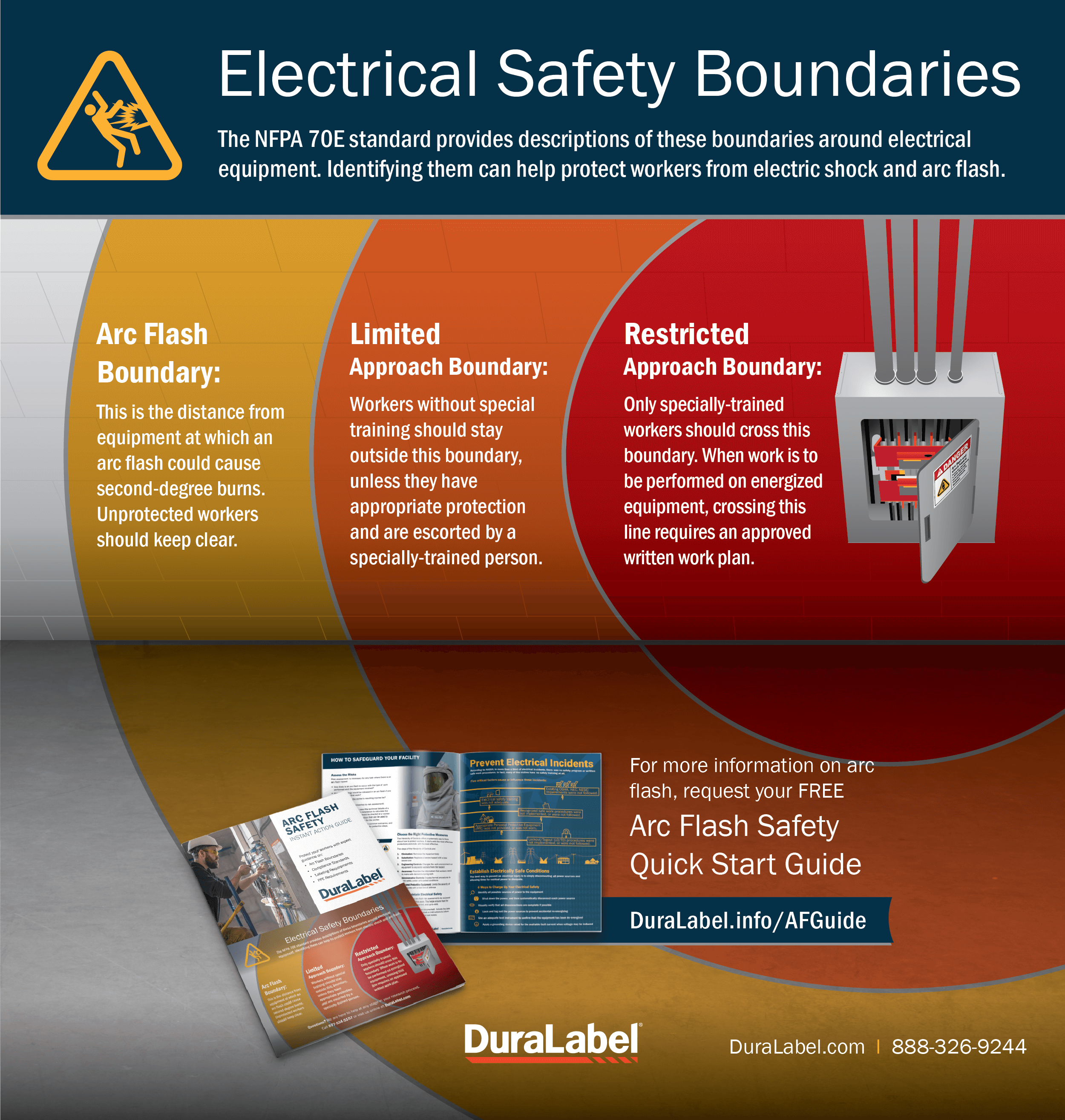

Arc Flash Labeling Quick Start Guide

Download DuraLabel's Arc Flash Labeling Quick Start Guide to improve your facility's arc flash safety. Learn about hazard areas, PPE requirements, & more!

Download

Pipe Marking Quick Start Guide

Learn how to identify pipe contents and hazards with this free Pipe Marking Quick Start Guide. Includes color codes, standards, & an inspection worksheet.

Download

Floor Marking Quick Start Guide

Learn how to create safe pathways for pedestrians and vehicles. Download our free Floor Marking Guide and lead your workers to a more efficient workplace!

DownloadCase Studies

How Ardagh Glass Packaging Improved Asset Management

DuraLabel Toro Max enhanced Ardagh Glass Packaging's labeling, improving safety, compliance, and productivity with durable labels for asset management.

Read More

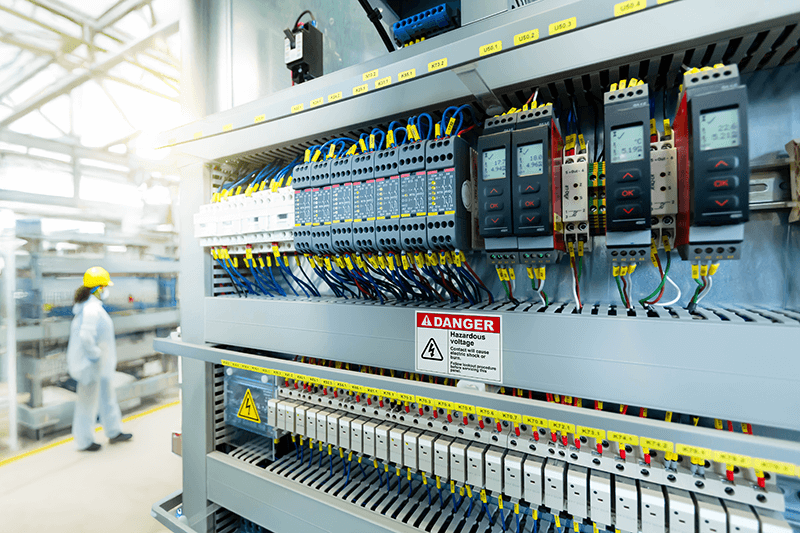

How KSG Improved Electrical Safety with DuraLabel Custom Labels

See how KSG Consulting Engineers improved safety and compliance with durable, customizable labels for arc flash and shock hazards using DuraLabel.

Read More

How DSM-Firmenich Optimized Labeling Efficiency with DuraLabel

DSM-Firmenich boosted labeling efficiency and safety with DuraLabel Toro Max, replacing an outdated system for clearer, consistent labels and workflow.

Read More

How Big River Steel Streamlined Labeling with DuraLabel Print Systems

Big River Steel enhanced safety and efficiency with DuraLabel's Toro Max Industrial Label Printers. Streamlining their organization and labeling processes.

Read More

How Booth & Associates Utilized Arc Flash Labeling for Client Service

See how Booth & Associates made custom arc flash labels in-house with the DuraLabel Toro Print System, improving compliance, efficiency, & client service.

Read More

How Metal-Detectable Labels Improved Efficiency at JR Simplot

Discover how Simplot's Moses Lake facility improved safety and efficiency with durable, FDA-compliant Metal Detectable Labels from DuraLabel.

Read MoreVideos

Kodiak Max Industrial Sign and Label Print System

Take control of your labeling needs with the Kodiak Max Sign and Label Print System, offering easy-to-load cartridges and compliance-ready templates.

WATCH NOW

Toro Max Industrial Label Printer

Explore the features of the Toro Max Industrial Label Printer for efficient, high-quality label printing in industrial environments.

WATCH NOW

LabelForge PRO: The Easy-to-Use Software for Anyone, Anywhere

See how LabelForge PRO design software saves time & simplifies workplace safety. Customize & print industrial labels in seconds on DuraLabel print systems.

WATCH NOW

Tough-Tested Premium Vinyl Label Supplies

Explore DuraLabel Tough-Tested premium vinyl supplies—designed for durability & performance in the most challenging environments. DuraLabel for tough jobs.

WATCH NOWHOW CAN WE HELP?

Labeling Project Help

DuraLabel Product Support

Get help with DuraLabel products and support with using software. Making labels, troubleshooting, or product recommendations.

Visit Product Support Center

DURALABEL PRODUCTS

Are you ready to create your own signs and labels on-site and on-demand? Shop DuraLabel printers and supplies here!

LABELING SOFTWARE

LabelForge PRO Software allows you to create custom labels from scratch or utilize templates and modules to be compliant

FREE LABEL SAMPLES

See the quality of tough-tested DuraLabel supplies for your self with free label samples.

DURANEWS NEWSLETTER

Free monthly newsletter from DuraLabel provides industry insights and compliance news that keeps you up-to-date in labeling.

.png)