ANSI Cutting Standard

03

February,

2023

2 MINUTE READ

ANSI Cutting Standard

The American National Standards Institute (ANSI) has updated its hand protection classification standard from ANSI/ISEA 105-2011 to ANSI/ISEA 105-2016. The update improves standardization by refining cut resistant levels and by using a single testing method for determining cut resistance. This update is in response to the growing need for clearer standards for interpreting hand resistance ratings.

Upping the Standard

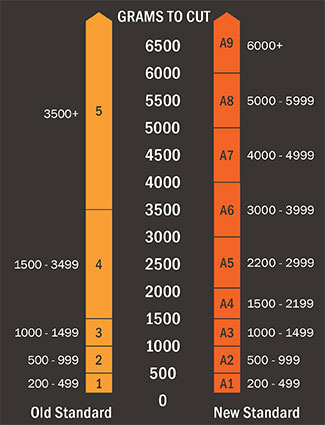

The previous standard made it difficult to identify a glove's actual cut resistance (a material's ability to resist damage from a sharp moving object). The difficulty arose from the old standard's six category classification system. A Category 5 glove, for instance, may have offered a cut resistance ranging from 3,500 grams to 6,000+ grams. This means that a Category 5 glove may have been able to resist damage from a moving blade that pressed against the glove with 3,500 grams of force or 6,000+ grams of force. The range of protection offered by Category 5 was too vast and made it difficult to recognize a glove's actual cut resistance.

The new standard seeks to eliminate the difficulty of selecting hand protection by adding four classifications, thereby reducing the range between each level. The new standard now includes nine classifications, A1-A9:

- A1 provides protection for light cut hazards (200-499 grams to cut)

- A2 provides light to medium protection from cut hazards (500-999 grams to cut)

- A3 provides light to medium cut protection (1000-1499 grams to cut)

- A4 provides protection for medium cut hazards (1500-2199 grams to cut)

- A5 provides medium to heavy protection from cut hazards (2200-2999 grams to cut)

- A6 provides protection from high cut hazards (3000-3999 grams to cut)

- A7 provides protection for high cut hazards (4000-4999 grams to cut)

- A8 provides high cut protection (5000-5999 grams to cut)

- A9 provides protection from high cut hazards (6000+ grams to cut)

In addition to the nine-category system, the update standardizes the testing method for defining cut resistance. Instead of multiple testing methods, a single method has been selected to ensure all gloves receive the same test. This will help to ensure that gloves, no matter the manufacturer, provide the same level of protection in a given class.

Workers in hospitals, warehouses, manufacturing facilities, and processing facilities are likely to encounter cut hazards in their workplace. In 2013, the U.S. Bureau of Labor Statistics (BLS) reported that there were over 139,000 lost time cases caused by hand injuries. Most of these injuries were cuts and lacerations. And each lost-time case resulted in about six days away from work, impacting each employer's bottom line.

To help reduce hand injuries, employees must be properly trained. OSHA requires that workers are trained to recognize and avoid workplace hazards. This includes understanding when PPE is needed and how it should be worn. Duralabel Compliance Services can analyze your workplace for hazards, develop training programs, and identify where PPE is required.

Overall, the new classification system will help improve worker safety by making it easier for workers and employers to select the proper Personal Protective Equipment (PPE) when working in hazardous environments.

What to Expect

Although OSHA does not require employers to follow the ANSI hand protection standard, OSHA's standard 29 CFR 1910.138 requires employers to select and require employees to use hand protection that will protect their hands from hazards. Selecting hand protection that adheres to ANSI/ISEA 105-2016 will help to ensure that that you will meet OSHA's requirements for cut protection.

RELATED RESOURCES

Hazardous Chemicals Overview

In the eyes of OSHA, hazardous materials run the gamut from household cleaners to deadly gasses. Effects can ...

Read

Available Fault Current

The National Electric Code, or NEC, requires that equipment be marked with the available fault current, and ...

Read

NEC 110 Labeling Requirements

The most recent NEC Article 110 had new labeling requirements updated in 2011. The latest labels are for ...

Read.png)