Tips to Make Air Compression Safety a Breeze

03

February,

2023

3 MINUTE READ

Compressed air is useful for a variety of actions in the industry: to power tools, atomize paint, and so much more. It has safety benefits such as being able to run without shock hazard, and compressed air is safe to use in areas where there may be combustible gas. However, compressed air can also be very dangerous and should be used properly. It's high pressure that comes with high risk. For example, in June, a firefighter in Ohio died from accidental injuries involving a compressed air tank explosion. Even in the most careful situations, compressed air has hazards. So, it is fair to say that compressed air is nothing to fool with, but the number of horseplay issues with compressed air still is a safety issue in today's workplaces. Recently, a man was arrested after he injected a co-worker with a lethal amount of compressed air at an industrial equipment manufacturing plant in Japan.

"It was a tragic accident but not the first of its kind," police said in a statement. "The release of the air into the body probably damaged (the worker's) lungs, causing death."

Hazards in the Air

An evaluation of Bureau of Labor and Statistics data over six years shows that there is an average of 124 deaths each year from caught by or compressed by equipment. Compressed air is listed among the subcategories of those death causes and the category does not include deaths caused by moving equipment or machinery. Safety best practices and proper use of compressed air should be followed at all times. According to the Occupational Safety and Health Administration, employers in general industry should not allow employees to use compressed air for cleaning themselves or their clothing. If cleaning must be done, compressed air must be lowered to 30 pounds per square inch (psi) and chip guards are advised, according to OSHA. However, blowing debris only moves dirt, metal shavings, and other industrial debris. A vacuum to suck debris from clothing or equipment would be more effective and safe. Other factors to consider for safety:

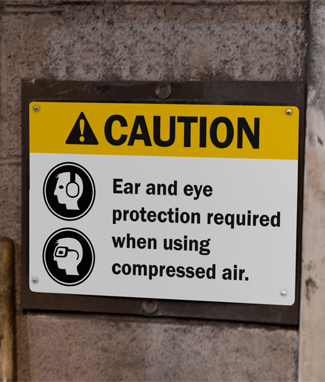

- Compressed air can damage eyes, skin, ears, the respiratory system, and even the bloodstream as the result of an uncontrolled release and having inadequate personal protective equipment. For example, a worker without hearing protection who is using compressed air at a 40 psi can rupture an eardrum and air can enter the brain.

- Compressed air can contain particulates, oil, dust, and other items that do not get filtered out. According to OSHA data, a worker using a compressed air machine in 2008 was injured when air and debris went into his eye and scratched it.

- Blowback can contain production debris. According to OSHA data, in 2014, a worker was struck by debris during high-pressure cleaning and was subsequently injured.

- Air compressors contribute to hazardous workplace noise levels, which can cause hearing damage.

- Review manufacturer's instructions to ensure that the proper tools and attachments are available for worksite air compressors. Safety devices can be employed on the muzzle of the tool to prevent ejection of fasteners. A mine worker received broken bones and required surgery in 2015 after using compressed air to test leaks during a nitrogen pipe inspection. The pressure rose to about 85 psi, and a pipe end fitting coupled to the pressure manifold separated from the pipe end and knocked the worker off his feet.

Compressed Air Safety

Industrial safety and health managers can easily increase safety in working with and around large industrial compressors. Create a workplace safety program and training that provides guidelines for safe use of compressor systems and air storage that includes recommendations from the manufacturer. Remind workers to wear safety glasses, face shields and other personal protective equipment. Some machines can start suddenly without warning and compressed air working areas can benefit from signage. These machines store large amounts of air under pressure and should have regular inspections and maintenance for safety. Ensure employees follow safe maintenance practices such as lockout/tagout. Use valve tags as a way to remind employees to not go over psi limits. Identify compressed air lines with pipe labels that also show the maximum working pressure. Remind workers to turn off pressure hoses when not in use.

RELATED RESOURCES

Workplace Safety During the Coronavirus Pandemic

Workplaces and their employees can stay on top of coronavirus prevention and potential spreading through ...

Read

USDA Increases Poultry Processing Line Speeds

Having concerns for worker safety as well as worries over other health hazards, OSHA and the USDA initially ...

Read

Five Safety Lessons Learned from the Demise of Titanic

Disasters and emergencies happen daily. However, we can learn from those mistakes and move forward for ...

Read.png)