Lean Tools

03

February,

2023

4 MINUTE READ

Five of the Most Helpful Lean Tools

Lean manufacturing uses many lean tools to improve production and efficiency by getting the most out of each resource. The goal of lean manufacturing is to find better ways to do things: requiring less effort, less time, and fewer resources. Some lean tools may be more appropriate for one business than another. However, Kaizen, 5S, Kanban, Value Stream Mapping, and Focus PDCA are among the most useful lean tools.

Kaizen

Kaizen is a lean tool that, when used correctly, fosters continuous improvement in quality, technology, processes, productivity, company culture, and safety. Created in Japan after World War II, Kaizen was used to help rebuild after the war.

Kaizen leverages knowledge and ingenuity from every employee, from upper management to the cleaning crew. As a result, suggestions for improvement come from every area of the business: production, procurement, management, logistics, finance, and so on. In most cases, individual improvements don't lead to major changes by themselves; rather, a continuous stream of small changes leads to major improvements in productivity, safety, and effectiveness while reducing waste.

A more modern use of Kaizen is to plan events, commonly known as Kaizen Events. Kaizen Events are official activities designed to create rapid change in the workplace. Used in support of the Kaizen process, these events target specific areas that need to be improved. Intense effort is then spent until the targeted area has been improved, usually over the span of one or two weeks. This approach is especially useful in getting people on-board with Kaizen because it results in dramatic changes in a short period-of-time. Kaizen Events should be used to support the overall Kaizen process.

Companies that practice Kaizen develop a culture in which employees feel empowered to make suggestions anywhere improvements can be made, whether in their own department or elsewhere.

5s

The 5S system is designed to improve efficiency through a systematic approach to organization and cleanliness in the workplace. The system includes five fundamental guidelines (five S's) that help improve workplace efficiency. The five S's are Sort, Set, Shine, Standardize, and Sustain. In practice, 5S makes workplaces more efficient and effective by:

- Removing unneeded items from each work area (Sort)

- Customizing each unique work area to maximize efficiency (Set)

- Cleaning each work area after every shift to help find and eliminate issues before they become major problems (Shine)

- Documenting improvements so they can be more easily applied in other work areas (Standardize)

- Making sure each step is repeated to ensure continuous improvement (Sustain).

As a lean tool, 5S is used in many industries, including manufacturing, software, and healthcare. It can be one of the easiest lean tools to start with, and it can be used with Kaizen and Kanban to create the most efficient workplace possible.

Kanban

Kanban is a visual production system in which a supply of parts is delivered to the production line as-needed, increasing efficiency. This lean tool works by making sure that workers have what they need, where they need it, and when they need it.

Historically, employees used Kanban cards to signal when they needed more parts, and new parts were not delivered until there was a card signaling a demand for new parts. More recently, physical Kanban cards are being replaced by a system that electronically signals demand, using specialized software. More commonly known as E-Kanban, the system can automatically request new parts using a series of barcodes that are scanned to signal when new parts are needed.

Using Kanban, employers can more easily manage inventory and reduce unneeded stock focusing, instead, on the items that need to be stockpiled. In turn, facilities can react to actual needs, rather than making guesses to anticipate the future, reducing waste and improving efficiency.

Kanban is entwined with Kaizen in that teams and individuals are encouraged to participate in continuously improving Kanban solutions and overall production processes. Kanban, as a lean tool, can be implemented in conjunction with Kaizen and 5S.

Value Stream Mapping

Value Stream Mapping (or VSM) is a visual lean tool that helps organizations optimize manufacturing and production.

Value stream maps are typically used to analyze the current process, highlight problems, and develop solutions for a system-wide change. As the name suggests, VSM provides a visual aid or map that helps participants understand the current problems by:

- Displaying the interaction between all items within the process

- Bringing secondary items to the forefront (scheduling, department workflow, material management, etc.)

- Visually representing information and material flow throughout the process

By visually mapping the relationships of all items within a process, potential problems and losses (wasted time, resources, or materials) are easier to identify. Potential solutions become clear. As the process continues, solutions are visually represented in a manner that allows all parties to understand the impact or change to the original process. A system-wide process change can then be implemented much more effectively. Through the VSM life-cycle, all new or updated processes are represented by an updated visual map, which allows the process of improvement to continue. Because this lean tool supports continuous improvements, it can be used in support of Kaizen.

Focus PDCA

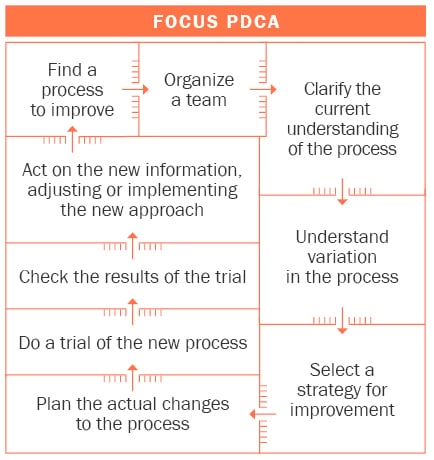

Focus PDCA is an organized, logical approach to improving business processes. It is a variation of the original Plan-Do-Check-Act process, and it includes steps that its predecessor omits. This lean tool's strength comes from its clear, no-nonsense steps.

The purpose of FOCUS PDCA is to provide a structure that guides the process of problem solving and process improvement. This approach establishes a comprehensive analysis, response, action plan, and feedback loop to ensure success.

How Can Duralabel Help with Lean Manufacturing?

Proper labeling and signage play an important part in implementing any lean tool. Whether you need large graphics during Value Stream Mapping or barcodes to kickstart Kanban, Duralabel has you covered.

Become lean by using 5S floor and aisle marking. Learn how PathFinder 5S floor marking, wayfinding, and safety tapes can improve safety and increase efficiency in warehouses of all sizes. Duralabel offers an in-depth Best Practice Guide to Floor Marking to help get you started.

Need more information about lean manufacturing? Duralabel has a wide variety of Best Practice Guides and articles to help make Lean part of your company. Download the free 5S guide today.

RELATED RESOURCES

Is Batch Production the Right Production Method for Your Organization?

The Myth of Large-Batch Production Manufacturers of everything from cakes to computer chips have many ways of ...

Read

Muda, Mura, Muri

One of the most important goals of lean manufacturing is the elimination of waste. Taiichi Ohno, father of ...

Read

Four Types of Wayfinding Signs

Think about the last time you passed through an airport, navigated a highway interchange, or went shopping at ...

Read.png)