Muda, Mura, Muri

03

February,

2023

3 MINUTE READ

One of the most important goals of lean manufacturing is the elimination of waste. Taiichi Ohno, father of the Toyota Production System (TPS), defined three categories of waste: Mura, Muri, and Muda. While Muda is the most widely known-the seven wastes-Muri and Mura are equally important to understand.

Muda

Muda refers to processes or activities that don't add value. These types of waste do not help your business or workers in any way. They increase costs and make tasks take much longer than they should. These wastes are defined in TPS as follows:

- Overproduction occurs when items are manufactured before they are required.

- Over-processing occurs when more work is put into a product or service than is actually required.

- Inventory is important, but storing too many or too few supplies and finished goods increase costs and can take valuable space.

- Transportation is the movement of products and supplies from one area to another.

- Motion is the physical movement of a person or machine required to complete work.

- Waiting is when work or projects come to a halt or slow because machines have yet to finish producing the required goods, products have not arrived, or some other task is holding up the rest of the project.

- Defects occur when errors and rework are created because of your processes.

Finding and eliminating Muda is essential if you want to reduce costs, improve efficiency, and increase profits. However, if you don't also address Mura and Muri, these benefits will be inconsistent or may even fade over time.

Mura

Mura is a type of waste caused by unevenness in production and services. It is also caused when standards are non-existent or are not followed. One common example is when companies ramp up production to meet targets, even when there is no customer demand. This forces the sales department to rush to try to fill orders and creates a burden as the shipping department rushes to ship products before the end of the month.

The result? Defects are manufactured into products. Customers receive inconsistent products or services. The production floor struggles to complete large orders and becomes idle as orders slow. Even more concerning is that Mura creates Muri (overburden), which in turn undermines efforts to eliminate the seven wastes of Muda.

Muri

The third category of waste is the result of tasks or processes that are overly difficult or ones that overburden workers. For the most part, this is caused when workers:

- Lack proper training

- Have no standards to follow

- Are given the wrong tools for the job

When workers lack the right tools for the job, for example, tasks become much more difficult, taking more time and potentially damaging the product. Working sheet metal with the wrong hammer and dolly will damage the panel you are working on-tripling the time it takes to complete the task and requiring products to be reworked.

In the same manner, using your email inbox to manage the tasks you must complete makes the task more difficult than it should be. Keeping emails to remind you of tasks to complete causes hundreds, if not thousands of emails to accumulate. As a result, it takes too long to find important information and may cause you to overlook important information, potentially causing projects to fall behind schedule or causing others to stop their work as they wait for a response.

Eliminating Muda, Mura, and Muri

The purpose of lean manufacturing is to find and eliminate Muda, Mura, and Muri, improving quality, safety, and efficiency. One lean tool that can help you eliminate these forms of waste is the 5S system. 5S helps to de-clutter, clean, and organize the workplace using the five "S" principles: sort, set in order, shine, standardize, and sustain.

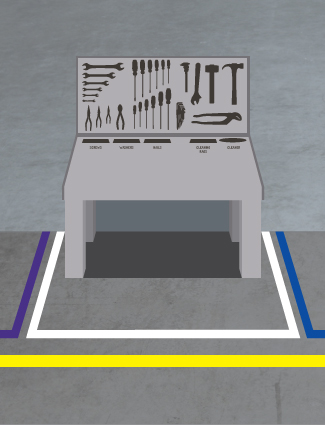

Sort is the first step in 5S. During this phase, you remove tools, supplies, and equipment that are not part of the work process. This declutters the workplace, freeing up space that was previously ill-used.

Set in Order is the next step, requiring you to organize the workplace and everything in it to improve the flow of work, based on how work is actually done.

Shine, the third step, requires you to clean the workplace and restore everything to its original condition. This makes it easier to spot equipment and product defects that may have otherwise been hidden.

Standardize, the fourth step, requires you to develop rules that will ensure work is completed consistently and that 5S is applied uniformly and regularly.

Sustain is the final step of 5S. It requires that you work to ensure 5S becomes a daily habit.

5S and Lean Resources from Duralabel

The 5S system provides a systematic method for improving your workplace. Learn more about how 5S can improve your workplace with the comprehensive Best Practice Guide to the 5S System by Duralabel, ensuring you have the tools and training needed to make 5S successful.

Duralabel full line of visual communication tools can support your 5S program. DuraLabel industrial label & sign printers and supplies enable you to print labels to identify tools, equipment, and supplies. Meanwhile, custom, color-coded labels will help workers identify categories of tools, supplies, and more.

Streamline your workplace with Duralabel line of PathFinder floor marking tapes. Ensure everything has a place by outlining spaces for workstations, supplies, and so forth. Create lanes for powered vehicles and workers, improving safety and helping work flow efficiently.

Ready to get started reducing facility waste and improving productivity and safety? Download our free 5s Color Code Chart below to use as a resource when planning your facility flow.

RELATED RESOURCES

Cross-Docking

What is Cross-Docking? At its most basic, cross-docking establishes a speedy, efficient system for unloading ...

Read

5S Methods Enhance Green Manufacturing

Manufacturing industries play a tug-of-war between the public and private sectors, each demanding the ...

Read

Four Types of Wayfinding Signs

Think about the last time you passed through an airport, navigated a highway interchange, or went shopping at ...

Read.png)